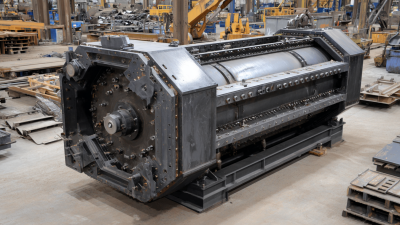

In the ever-evolving world of mining and aggregate production, the efficiency of crushing operations is paramount. A key player in this process is the jaw crusher, a versatile and robust piece of machinery known for its reliability and durability. To maximize the performance of jaw crushers, it is essential to focus on the high-quality components that comprise these machines. The right jaw crusher parts can significantly enhance operational efficiency, reduce downtime, and ultimately lead to cost savings.

As we look ahead to 2025, understanding the vital components that can optimize jaw crushers will be crucial for mining professionals aiming to maintain a competitive edge. From wear-resistant liners to innovative toggle mechanisms, various parts play a pivotal role in the functionality and longevity of a jaw crusher. This article will explore the top jaw crusher parts that are set to transform mining operations, ensuring that businesses can adapt to the dynamic challenges of the industry while maximizing productivity and efficiency.

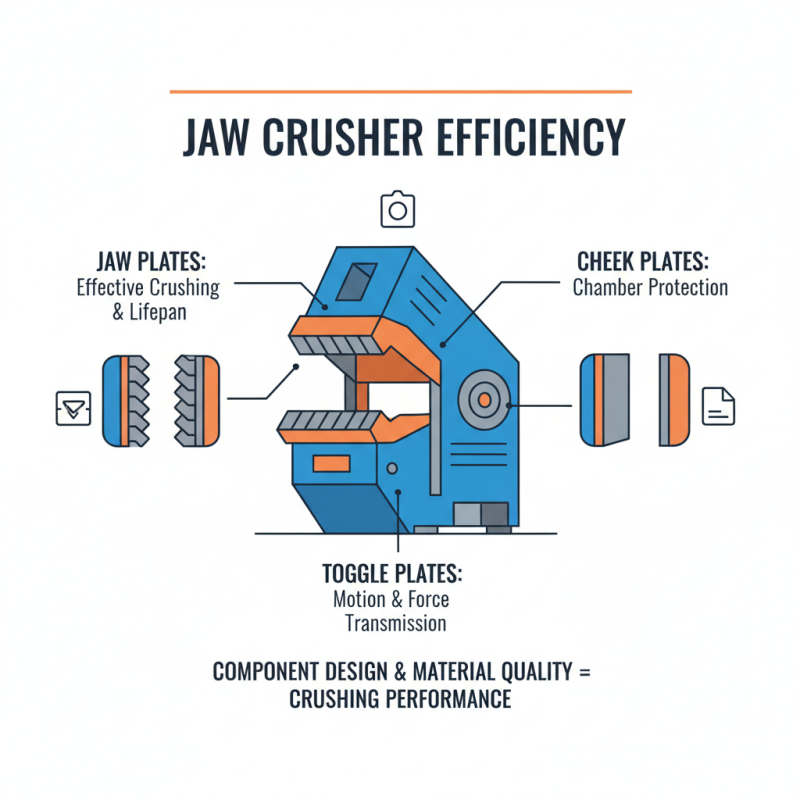

When it comes to the functionality and efficiency of jaw crushers, understanding the essential components is crucial. The main parts include the jaw plates, which are vital for crushing material; they must be durable and capable of withstanding high levels of wear. These plates come in different designs, such as smooth or corrugated, depending on the material being processed. Optimizing the selection and maintenance of jaw plates can significantly enhance the performance of the crusher.

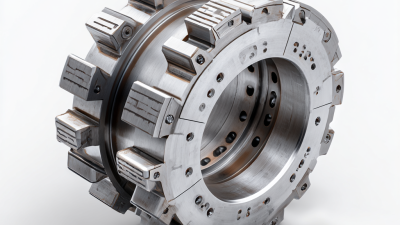

Another critical component is the pitman, which is the moving part that exerts force on the material being crushed. Its design and strength are essential for ensuring smooth operation and effective energy transfer during the crushing process. Additionally, the toggle plate plays a pivotal role in protecting the machine from overloads by acting as a mechanical fuse. Regular inspection and timely replacement of these components help maintain the crusher's operational efficiency and longevity. Understanding these parts allows mining operations to make informed decisions about their equipment, ensuring they achieve optimal performance in their crushing tasks.

The efficiency of a jaw crusher is largely dictated by its individual components, each playing a crucial role in the overall process of material reduction. Key parts such as the jaw plates, toggle plates, and cheek plates significantly influence the crusher’s ability to crush materials effectively. The design and material quality of these components can either enhance the performance of the machine or lead to premature wear and inefficiencies. For instance, using high-quality jaw plates made from premium materials can increase the lifespan of the parts while ensuring a more effective crushing action.

Furthermore, the correct alignment and maintenance of these parts contribute to optimal efficiency in mining operations. When components like the bearing systems and eccentric shaft are in proper working order, they facilitate smooth operation and reduce operational disruptions. Regular inspections and timely replacements of worn-out parts can prevent performance dips, ensuring that the jaw crusher operates at peak efficiency. Understanding the interdependence of these components enables mining professionals to make informed decisions that ultimately boost productivity and reduce downtime in their operations.

Recent Innovations in Jaw Crusher Design and Technology have significantly enhanced mining efficiency, addressing key challenges such as wear and tear, energy consumption, and material handling. Today's jaw crushers incorporate advanced materials such as high-strength, low-weight alloys that increase durability while reducing overall machinery weight. According to a report by the Mining Equipment Association, the adoption of these new materials has led to a 15% increase in lifespan and a 10% decrease in operational costs for mining companies. This is a crucial development for operations aiming to maximize productivity within tightly controlled budgets.

Moreover, the integration of digital technology into jaw crushers is streamlining maintenance and monitoring processes. With the implementation of IoT sensors, modern crushers can now provide real-time data analytics on performance, enabling predictive maintenance that minimizes downtime. A study highlighted by the International Journal of Mining Science suggests that utilizing smart monitoring systems can lead to a reduction in costly repairs by up to 20%. Furthermore, these innovations are empowering operators with the data needed to optimize their crushing processes, thus enhancing overall plant efficiency.

**Tips:** Regularly review the data provided by smart monitoring systems to identify patterns and optimize your maintenance schedule. Additionally, consider investing in high-performance jaw crusher parts to further increase both durability and efficiency. Emphasizing a proactive approach in maintenance can significantly impact your bottom line.

This chart showcases the estimated performance improvements in jaw crusher parts in 2025 based on recent innovations in design and technology. The data reflects the percentage increase in efficiency based on various components that enhance mining operations.

When it comes to boosting mining efficiency, the role of high-quality jaw crusher parts cannot be overstated. The market is flooded with options, but selecting parts from top brands ensures durability and optimal performance. These premium parts are designed with advanced materials and engineering techniques, providing the best possible fit and integration into your existing machinery. By investing in reliable components, mining operations can minimize downtime and maximize productivity, essential factors in today’s competitive environment.

Tips for selecting jaw crusher parts include thoroughly researching suppliers and understanding their reputations in the industry. Look for manufacturers that emphasize quality control and have a track record of providing parts that withstand the rigors of mining operations. Additionally, consider parts that offer warranties or guarantees, which can further protect your investment and ensure you can maintain efficiency in the long run.

Moreover, keep maintenance in mind when choosing your parts. Regular inspection and replacement of worn components can prevent larger issues down the line. Having spare parts readily available from trusted brands can also significantly improve operational workflow, reducing delays caused by sudden equipment failures. Prioritizing quality parts will ensure your jaw crushers perform at their best, ultimately driving your mining efficiency forward.

Maintaining the longevity of jaw crushers is crucial for maximizing efficiency in mining operations. Regular inspections and timely replacements of worn parts can significantly reduce unplanned downtime. It’s vital to establish a comprehensive maintenance schedule that includes checking for cracks in the crusher jaws, monitoring wear patterns, and ensuring proper lubrication of moving components. Adequate attention to these areas not only sustains performance but also optimizes the lifespan of the equipment.

Tips: Always keep a log of maintenance activities. This helps identify patterns in wear and assists in predicting future needs. Implementing a preventative maintenance plan can save time and reduce costs associated with unexpected repairs. Additionally, investing in high-quality replacement parts can enhance the overall resilience of your machinery, ensuring that your operations remain smooth and efficient.

It's also beneficial to train operators on best practices for using jaw crushers, as proper handling can prevent unnecessary strain on the equipment. Regularly providing training sessions that focus on operational guidelines and safety measures will further bolster the longevity of your jaw crushers. Behind successful mining operations lies a commitment to effective maintenance strategies, which are essential for optimizing productivity and ensuring the reliability of machinery throughout its lifespan.

| Part Name | Material | Wear Resistance | Estimated Lifespan (Hours) | Maintenance Tips |

|---|---|---|---|---|

| Jaw Plate | Manganese Steel | High | 2000-3000 | Regular inspection and replacement when worn |

| Toggle Plate | Steel Casting | Medium | 1500-2500 | Check for cracks and alignment issues |

| Side Plate | High Carbon Steel | Medium | 1000-2000 | Ensure proper fit and alignment |

| Hammer | Alloy Steel | High | 1500-3000 | Monitor for wear and replace as necessary |

| Bearing | Bronze | Medium | 3000-5000 | Regular lubrication and alignment checks |