The efficient crushing of stone is a critical process in various industries, contributing significantly to construction, mining, and aggregate production. A key component in this process is the jaw plate, which directly impacts both the performance and longevity of crushing machinery. According to industry reports, the global stone crushing equipment market is projected to reach $8.5 billion by 2025, highlighting the growing demand for reliable and effective solutions. In particular, high-quality "Jaw Plates For Crushing Stone" are essential for maximizing efficiency and minimizing downtime in operations. These plates not only affect the crushing ratio but also enhance the overall productivity of crushers. As the market continues to evolve, selecting the best jaw plates becomes crucial for companies aiming to optimize their stone processing capabilities.

When selecting high-performance jaw plates for stone crushing, it's essential to focus on specific features that contribute to enhanced efficiency and durability. High-quality jaw plates significantly impact the overall productivity and operational costs in quarrying and mining industries. According to a report from a leading industry analysis group, using optimized jaw plates can improve crushing efficiency by up to 20%, which is crucial for maintaining competitive outputs.

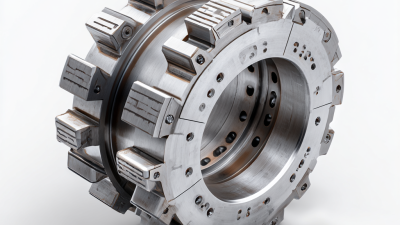

One key feature to consider is the material composition of jaw plates. Plates made from high manganese steel, for example, exhibit superior wear resistance and can withstand extreme impact forces, increasing their lifespan and reducing downtime caused by replacements. Furthermore, industry insights suggest that jaw plates with built-in enhancements such as additional carbide overlays or specific geometrical designs can lead to a more efficient material flow, further maximising the crushing capacity of equipment by approximately 15%.

Another critical aspect is the design and manufacturing techniques employed. Advanced manufacturing processes, such as precision casting and surface hardening treatments, ensure that jaw plates have the necessary strength and durability. Data shows that jaw plates produced with these techniques tend to outperform standard plates in terms of wear resistance, which can result in reduced operational costs over time. Investing in high-performance jaw plates is not just about initial costs; it’s a strategic choice for long-term productivity gains.

The durability and efficiency of jaw plates are significantly influenced by the quality of the materials used in their manufacturing. Research from the Mining Research Institute indicates that high-quality jaw plates can lead to a 20-30% increase in performance efficiency when crushing stone. This is primarily because superior materials exhibit enhanced wear resistance, allowing for prolonged operational cycles and reduced downtime for maintenance. Manufacturers employing advanced alloys and composite materials often report fewer failures and extended lifespan, contributing to overall operational cost savings.

Moreover, the specific characteristics of the material, such as hardness, toughness, and corrosion resistance, play vital roles in how well jaw plates perform in varied crushing environments. A study published in the Journal of Materials Science found that jaw plates made from manganese steel could endure impacts better than those constructed from lower-grade materials. This leads to decreased frequency of replacements and improved efficiency in crushing operations. Therefore, understanding the impact of material quality on jaw plate performance is essential for industry players aiming to enhance their crushing efficiency and minimize operational costs.

The design of jaw plates plays a crucial role in enhancing the efficiency and output quality of stone crushing operations. Recent innovations in crushing technology underscore the importance of optimizing jaw plate geometry to achieve superior performance. For instance, the introduction of new jaw plate designs that prioritize swing mechanics and chamber configurations has been shown to significantly affect throughput rates and final product quality. A report highlights that adjusting the crushing parameters, including feed mass and plate curvature, can lead to optimal material fragmentation and reduced energy consumption during the crushing process.

Moreover, advancements in wear components have been linked to increased uptime and operational efficiency. Facilities employing these high-performance components reported notable improvements in productivity metrics. Data suggests that operations leveraging innovative crushing solutions have achieved up to a 20% increase in wear life and output compared to traditional systems. Such advancements not only enhance crushing capabilities but also contribute to the overall sustainability and economic viability of aggregate production, making the selection of the right jaw plate design paramount for industry players aiming to stay competitive in the market.

When it comes to optimizing crushing performance in stone processing, the choice of jaw plates is critical. This comparative analysis delves into the top seven jaw plates that enhance efficiency and productivity. Each model stands out for unique features, such as material quality, design advancements, and compatibility with various crushing machines, ensuring operators can find the perfect match for their specific needs.

Selecting the right jaw plate can significantly impact both the lifespan of the equipment and the quality of crushed material. Therefore, it’s essential to consider factors like the hardness of the stone and the type of crushing process employed. For instance, opting for a jaw plate made from high-manganese steel can increase durability and reduce wear, prolonging the intervals between replacements.

Additionally, regular maintenance and timely inspection of the jaw plates can prevent unexpected breakdowns and costly repairs. Operators should also keep an eye on the wear patterns and adjust their crushing techniques accordingly. Employing these tips will not only lead to enhanced operational efficiency but will also ensure that the machinery runs smoothly, yielding better results over time.

To ensure the longevity and optimal performance of jaw plates used in stone crushing, regular maintenance is essential. One critical aspect of this maintenance is checking for wear signs regularly. Over time, jaw plates can develop grooves, cracks, or excessive wear that can reduce their efficiency. Implementing a regular inspection schedule allows operators to identify these issues early, preventing costly downtimes and ensuring consistent performance.

Another important maintenance tip is to ensure proper lubrication of the jaw plates. Adequate lubrication reduces friction and heat generation, extending the life of the plates. Using high-quality lubricants can help to minimize wear and tear, allowing the jaws to operate smoothly. Additionally, operators should ensure that the crushing materials are free from contaminants, as foreign objects can cause significant damage, leading to premature wear. By maintaining a clean work environment and monitoring the condition of the jaw plates, operators can significantly enhance their efficiency and lifespan.