In the world of mining, efficiency is paramount. The choice of Mining Stone Crusher Parts significantly impacts operational productivity. According to John Smith, a renowned expert in the mining sector, “Choosing the right parts can make or break your operation.” These components are essential for crushing materials effectively.

Mining Stone Crusher Parts vary in quality and performance. It is crucial to select durable and reliable pieces. Some products may look good on paper but perform poorly in the field. This inconsistency can lead to unexpected downtime and increased costs.

Understanding the nuances of Mining Stone Crusher Parts is essential. Some parts might fail after short usage. Others may require frequent maintenance. The objective is to avoid these pitfalls. Investing in high-quality parts may seem costly upfront but can save money in the long run. Striking the right balance is key for any mining operation. Reassessing current choices occasionally might prove beneficial.

In the mining industry, stone crushers play a vital role in material processing. Knowing the components of these machines is essential for efficiency. Key parts include the jaw, cone, and impactor, which serve different functions. The jaw crushes large rocks while the cone handles medium-sized materials. Impactors are ideal for producing finer aggregates. Each part must work in unison for optimal results.

Regular wear and tear can compromise performance. Therefore, frequent inspections are crucial. Operators often overlook small cracks or slips in the machinery. Addressing these issues can prevent larger breakdowns. Issues like misalignment can lead to uneven wear. This not only affects productivity but also increases operational costs.

Understanding the roles of these components helps optimize the crushing process. It's not just about replacing worn parts; it's about knowing when and how to do so. A proactive maintenance strategy can make a significant difference. Yet, many operators are unsure about their equipment's needs. Investing time in learning about these parts is often undervalued.

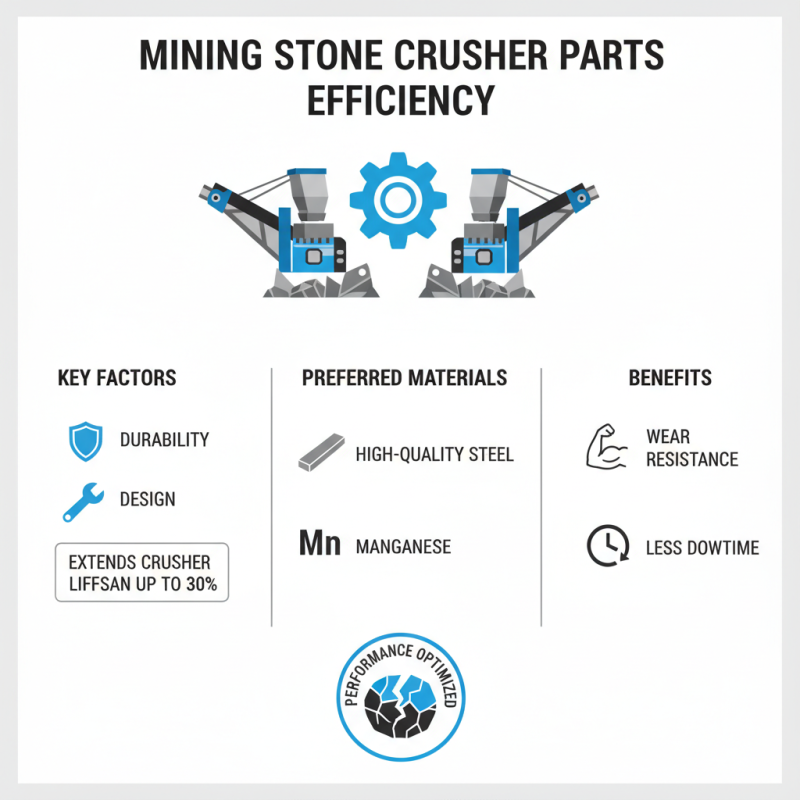

Efficient mining stone crushers rely heavily on their key components. Critical parts include the crusher frame, motor, and various crushing elements like jaws and cones. These components play a vital role in overall performance. Reports indicate that effective maintenance can extend the lifespan of these parts by up to 30%.

The crusher frame bears the brunt of the impact during operation. A robust design helps minimize vibrations and enhances stability. Additionally, the motor's power directly influences the crushing efficiency. It's essential to choose the right motor for specific operations, as a mismatch can lead to inefficiencies.

Tips: Regular inspections are necessary. Look for wear and tear on the jaws and other crushing elements. Replace parts before they fail to avoid unexpected downtime. It's also crucial to keep the machine lubricated. This simple step can reduce friction and prolong the life of critical components.

Finally, attention to detail in choosing materials can make a difference. High-quality steel can perform better and withstand harsh conditions. However, not all materials are the same. Testing and evaluating options is vital. Efficiency can be significantly improved, but it requires thoughtful choices.

Choosing the right materials for mining stone crusher parts is crucial. The durability and efficiency of these parts vary widely based on the materials selected. Common materials include high manganese steel, which provides excellent toughness and wear resistance. Additionally, certain alloys can enhance the lifespan of crusher parts.

However, not all materials perform equally under harsh mining conditions. Some parts may wear out quicker than expected, leading to increased downtime. A sharp focus on material properties can help mitigate this risk. Regular testing and evaluation are essential to determine how various materials hold up against specific rock types and crushing methods.

Another area to consider is the manufacturing process itself. Poorly manufactured parts, even from the best materials, can fail prematurely. Thus, meticulous attention should be paid to quality control. In the end, the selection of materials and the integrity of the manufacturing process go hand in hand. Making wise choices will lead to efficient and lasting performance in the mining sector.

Maintaining a mining stone crusher is vital for ensuring optimal performance. Regular inspections can help identify wear and tear. Checking parts like hoppers and jaws often prevents larger issues. Neglected equipment can lead to costly breakdowns. Operators should closely monitor lubrication levels to avoid overheating. Focusing on these points can save time and money.

Also, consider implementing a scheduled maintenance routine. For example, a monthly check on the conveyors and screens can catch problems early. Keeping a record of these maintenance tasks allows for better tracking of the equipment’s health. Regular replacements of worn-out parts will ensure continuous operation. A small delay in maintenance can result in significant downtime, which is counterproductive.

Crushing efficiency depends on proper maintenance practices. Inspecting and cleaning the discharge chutes can improve flow and productivity. It might seem tedious, but every detail matters. Lack of attention to minor issues can snowball into serious faults. There’s always room for improvement. By refining these practices, operators can enhance crushing operations.

When analyzing mining stone crusher parts, efficiency is key. Factors like durability and design can significantly influence performance. Recent industry reports indicate that well-designed parts can extend the lifespan of crushers by up to 30%. Materials such as high-quality steel and manganese are commonly preferred. These materials resist wear and tear more effectively, leading to less downtime.

Many mining operations overlook the maintenance of crusher parts. Regular inspection can prevent major issues. A study from the Mining Journal suggests that 60% of operational challenges are due to part deterioration. Operators should prioritize a maintenance schedule. This can enhance productivity and reduce costs.

Tips: Always store spare parts in a dry area. This minimizes rust and damage. Consider investing in training for your team. Knowledge of part specifications leads to better decisions and fewer mistakes. Proper documentation of part performance can also provide insights into future upgrades.