In the world of crushing operations, the efficiency of the "Stone Crusher Moving Jaw" is paramount. Industry expert, John Smith, emphasizes, "The moving jaw is the heart of any stone crusher." This crucial component plays a pivotal role in determining the overall performance of the machine.

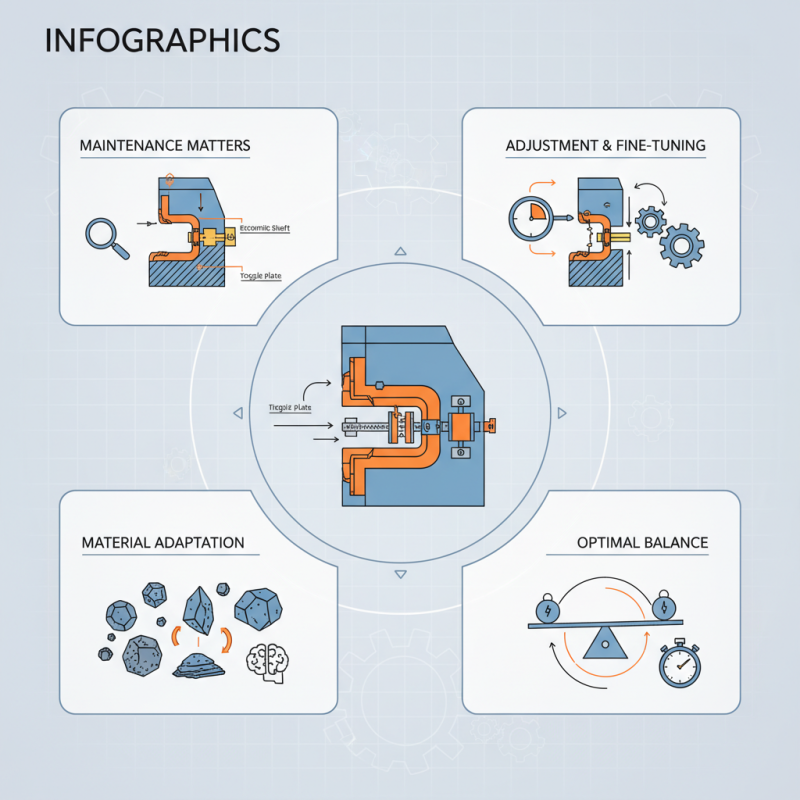

Understanding the design and mechanics of the Stone Crusher Moving Jaw can lead to significant improvements. However, many operators overlook maintenance, leading to suboptimal results. Regular inspections and timely adjustments can greatly enhance efficiency. A minor oversight can result in increased wear and reduced output.

Moreover, achieving the perfect balance in jaw movement is often a challenge. Experimentation and fine-tuning are vital for optimal crushing. Every stone material behaves differently, necessitating a thoughtful approach. Thus, operators must constantly reflect on their practices. Adapting strategies to cope with specific materials is essential for success.

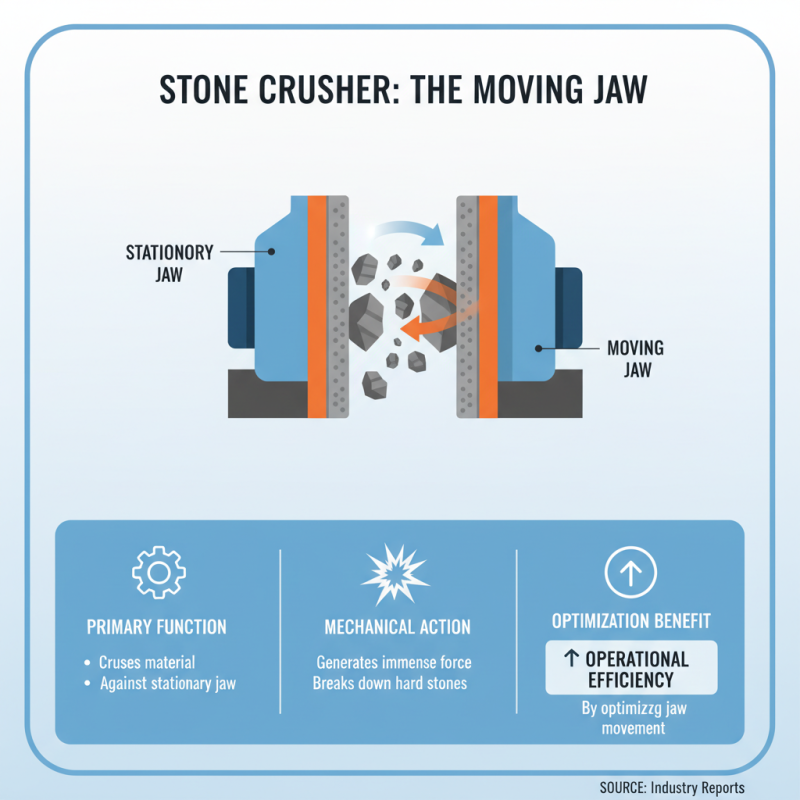

The moving jaw plays a crucial role in stone crushers, dictating the efficiency of the crushing process. Its primary function is to crush the material against a stationary jaw. This action generates a significant amount of force, allowing for the breakdown of hard stones into manageable sizes. According to industry reports, optimizing the movement of the jaw can lead to a 20% increase in operational efficiency.

Understanding the mechanics behind the moving jaw is essential. Small adjustments in gap settings can drastically affect output. An ideal setting maximizes throughput while minimizing wear and tear. For example, a jaw with a fixed gap of 100 mm can provide an optimal performance range for certain materials. However, this requires careful monitoring. Many operators overlook this aspect, leading to inefficiencies.

The wear patterns on the moving jaw are also telling. Uneven wear indicates misalignment or incorrect settings. Regular inspections can help identify these issues early. Industry data shows that proactive maintenance can reduce downtime and increase output by over 15%. Reflecting on these insights can highlight the importance of precise adjustments and regular checks in optimizing stone crushing operations.

When designing an efficient stone crusher moving jaw, several key features must be considered. The shape of the jaw is paramount. An optimized design enables better crushing action and reduces stress on components. A well-shaped jaw allows for uniform material flow and prevents blockages. This, in turn, enhances the overall performance during crushing operations.

Material selection also plays a crucial role. Using high-quality materials for the moving jaw can extend its lifespan significantly. However, not all materials perform well under high-stress conditions. It’s essential to test different alloys to determine the best fit for specific crushing tasks. Some materials may wear out too quickly, leading to increased maintenance costs.

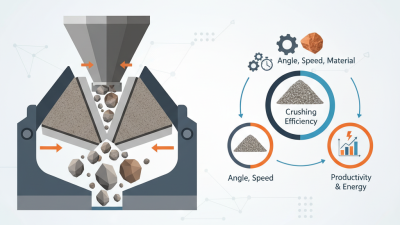

Another vital aspect is the angle of the jaw. Adjusting the jaw's angle can optimize the crushing process. A steeper angle may increase efficiency, but it can also lead to durability issues. Balancing these factors is vital for achieving optimal performance. This often requires ongoing assessment and fine-tuning. Learning from what doesn't work is just as important as understanding what does.

| Design Feature | Description | Impact on Performance |

|---|---|---|

| High-Carbon Steel | Moving jaws made of high-carbon steel for better durability. | Increased lifespan and reduced wear, enhancing efficiency. |

| Optimized Geometry | Jaw design with improved contours for material flow. | Enhanced crushing action and reduction of blockages. |

| Adjustable Toggle Mechanism | Allows for varying the crushing size and compression. | Provides flexibility in feed material size and improves output. |

| Heat Treatment | Process applied to increase material strength. | Reduces likelihood of cracking and extends service life. |

| Curved Jaw Design | Curved surface improves grip on materials during crushing. | Increases efficiency and uniformity in crushed output. |

Maintaining the moving jaws in stone crushers is crucial for optimal performance. Regular inspection helps identify wear and tear. Check for cracks or signs of fatigue in the jaw structure. Small fractures can lead to significant issues if left unchecked. Every week, a thorough cleaning should remove accumulated debris. This simple step can enhance operational efficiency.

Lubrication is another key aspect of maintenance. Ensure that moving parts are well-lubricated to reduce friction. A lack of lubrication can cause excessive heat and lead to premature wear. Sometimes, maintenance routines forget to address this area. A monthly review of lubrication practices can prevent costly repairs.

Additionally, operators should train themselves on the equipment. Understanding how the moving jaws work is vital. Misuse can lead to performance drops. Equipment manuals are often overlooked. Operators should read them carefully. Regular training sessions can reduce mistakes. Engaging team members in maintenance discussions encourages a culture of care.

Optimizing material flow through moving jaws in stone crushers is crucial for maximizing efficiency. Research indicates that an optimized jaw design can increase throughput by up to 30%. Key factors include the angle of the jaw and the size of the material being crushed. A jaw angle between 20 and 30 degrees optimizes compression forces while reducing wear on the moving parts.

Properly managing the feed size is essential. Feeding oversized materials can lead to blockages. This not only causes delays but also increases maintenance costs. Implementing a primary screening process can reduce these issues. In fact, studies show that using a pre-screen can boost overall process efficiency by 25%. It's vital to monitor the flow to avoid jams and ensure a smooth operation.

While enhancing jaw mechanics is important, operators should also reflect on maintenance practices. Regular inspections can identify wear patterns early. Ignoring these signs can lead to inefficient crushing and equipment failure. Keeping a close eye on the wear plates and ensuring optimal lubrication is necessary to avoid unexpected breakdowns. Adopting a proactive approach can save time and resources in the long run.

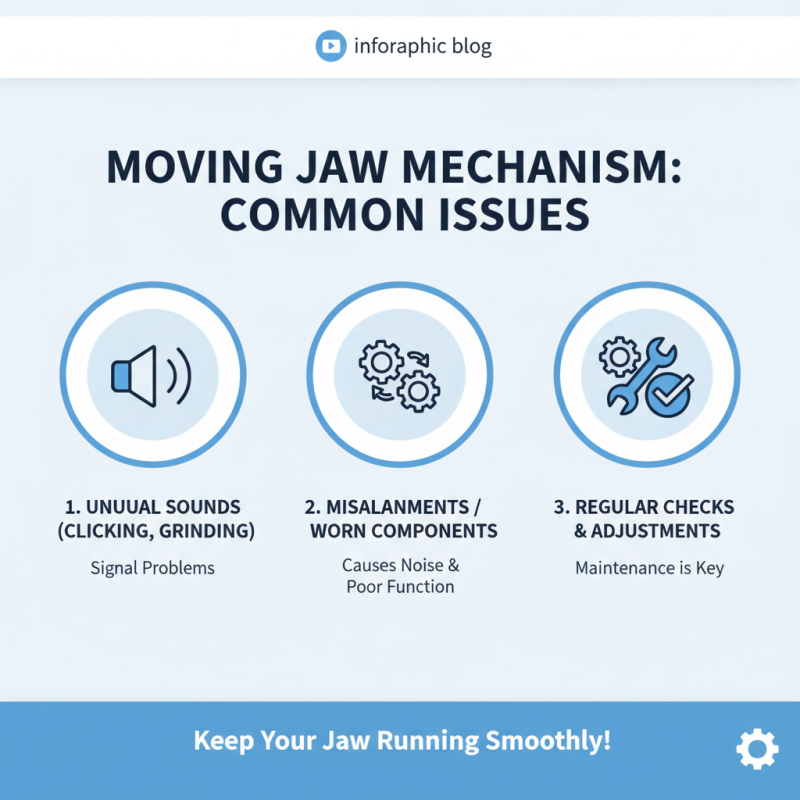

When dealing with moving jaw mechanisms, several common issues arise. Unusual sounds during operation often signal problems. These noises might indicate misalignments or worn components. Regularly check the jaw's condition and adjust as needed.

Vibration can also be a significant issue. Excessive vibration typically means loose parts or improper installation. Tightening bolts and securing mounts can help mitigate this problem. Take time to examine each joint carefully. Look for wear and tear; early detection makes a difference.

Tips for efficient operation include maintaining a clean environment around the crusher. Dirt and debris can lead to operational failures. Ensure lubrication is applied adequately. This keeps parts moving smoothly. Regular inspections can prevent severe breakdowns. Consistent monitoring leads to fewer surprises. Always keep an eye on the wear patterns to enhance longevity. Addressing these concerns promptly is essential for maintaining functionality and efficiency.