Choosing the right Mining Machinery Jaw Plates is crucial for optimal performance and longevity. According to industry expert John Smith, "The quality of jaw plates directly impacts the effectiveness of your machinery." This highlights the significance of selecting the best options for your needs.

Mining Machinery Jaw Plates come in various materials and designs. Each choice influences efficiency and maintenance costs. High-quality jaw plates reduce wear and tear on machinery. However, not all products live up to their promises, making the selection process complicated.

Many operators overlook the importance of proper fit and material. This oversight can lead to increased downtime and additional costs. Investing time in research pays off. When in doubt, consult with experts or manufacturers. Your choice in Mining Machinery Jaw Plates could determine your operation's success.

Jaw plates play a critical role in mining machinery. They are the main components that crush materials. Their durability directly affects performance and efficiency. The right jaw plates ensure better productivity and lower operating costs. A wear-resistant jaw plate can improve lifetime, but not all materials are suitable. Understanding material choices is essential for optimal results.

Here are some tips for selecting jaw plates. First, consider the hardness of the material you are crushing. Softer materials may not require heavy-duty plates. For harder rocks, tougher plates are a must. Evaluate the wear patterns on existing plates. Uneven wear may indicate misalignment. Frequent inspections can prevent costly downtime.

Think about the replacement cycle. Some jaw plates wear down quickly, while others last longer. Frequent replacements can disrupt operations. It’s essential to strike a balance between cost and longevity. Remember, the best choice might not always be the most expensive. Reflect on past experiences and adjust strategies. This approach can lead to more informed decisions in the future.

Choosing the right jaw plates is crucial for mining machinery. The materials used in their manufacturing can significantly affect performance. A study indicated that high-manganese steel is commonly used due to its excellent hardness and wear resistance. It can withstand significant impact forces. However, its brittleness at lower temperatures can lead to premature failure.

Another option is low-carbon alloy steel. It offers good ductility, but may not provide the same level of hardness as high-manganese steel. This trade-off means operators must assess their specific needs carefully. Some reports suggest that mixing materials can enhance durability. For instance, incorporating chromium or nickel can improve corrosion resistance. Yet, this approach is not without risk; you might face unexpected failures if not tested properly.

It’s essential to recognize that each material has limitations. The ideal choice often relies on the operating environment and material being processed. Regular testing and analysis of wear patterns can provide insights. Observing these factors ensures optimal performance and reduces unforeseen downtime. The aim should be to find a balance that maintains efficiency without overspending on exotic materials that may not suit every application.

| Material Type | Hardness (HRC) | Tensile Strength (MPa) | Ductility (%) | Cost (USD/kg) |

|---|---|---|---|---|

| Manganese Steel | HRC 12-14 | 689 | 20 | 2.00 |

| High Carbon Steel | HRC 30-35 | 700 | 15 | 1.80 |

| Alloy Steel | HRC 25-30 | 600 | 18 | 2.20 |

| White Iron | HRC 55-65 | 900 | 2 | 3.00 |

| Martensitic Steel | HRC 40-50 | 750 | 10 | 2.50 |

Choosing the right jaw plates for mining machinery involves careful consideration of several critical factors. One key element is material composition. High manganese steel is a popular choice due to its excellent wear resistance. This material can withstand harsh environments and heavy loads. However, it may not perform as well in extremely abrasive conditions. Some reports suggest that the hardness of jaw plates can significantly affect performance, with optimal values typically between 400 and 500 HB.

Another factor to consider is the design of the jaw plates. A well-designed profile can enhance crushing efficiency. According to industry analyses, the right jaw plate design can increase throughput by 17% compared to suboptimal designs. However, achieving the perfect balance between hardness and design can be a challenge. Testing different configurations helps in understanding their impact on material fragmentation.

Lastly, the operational environment plays a crucial role. For instance, a high-silica rock may require different jaw plates than softer minerals. Regularly assessing operational conditions allows for adjustments. Relying solely on initial data can lead to inefficiencies. Monitoring wear patterns is essential for making informed decisions about replacements.

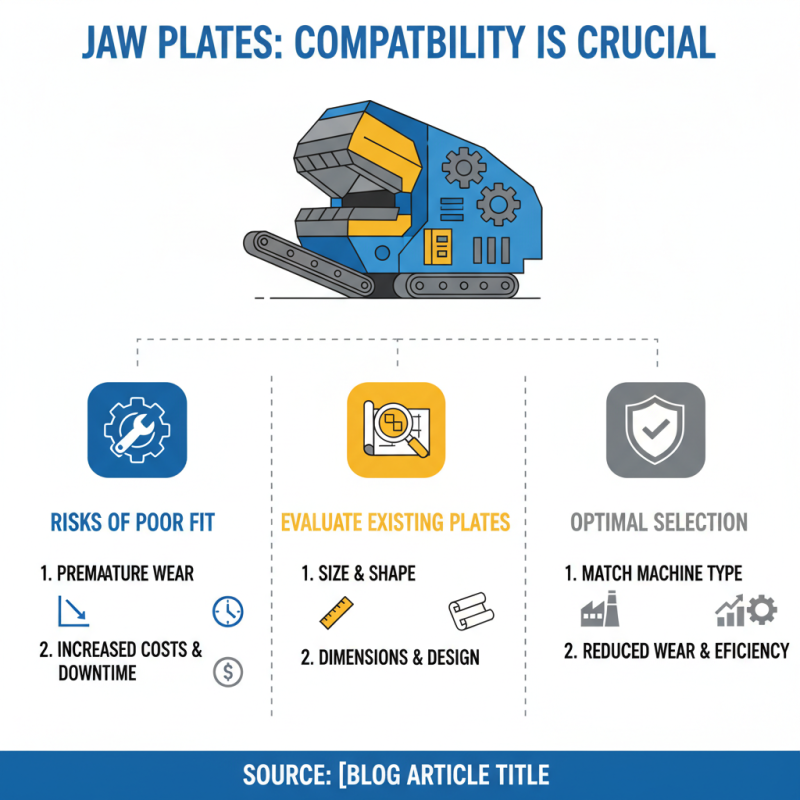

When selecting jaw plates for mining machinery, compatibility is crucial. Ignoring this can lead to inefficiencies. The wrong fit might cause premature wear. This leads to increased costs and downtime. Each machine type has specific requirements. Evaluate the size and shape of your existing jaw plates carefully. Check dimensions and design against your equipment.

Material choice also plays a significant role. Some materials wear down faster than others. Using the wrong material can affect performance and longevity. It’s important to consider the mining conditions. Harder ores require tougher jaw plates. Ensure that the selected plates can handle the specific challenges in your environment.

Sometimes, it's easy to overlook minor details. A slight mismatch can disrupt the entire operation. Regularly review your equipment performance to identify issues. Gather feedback from the operators, as they work closely with the machinery. This will help in making informed decisions in the future. Compatibility should always be a priority, not an afterthought.

When it comes to maintaining jaw plates, regular inspections are key. Look for signs of wear and damage. Cracks or excessive wear can lead to reduced efficiency. Don’t wait for major failures. Small issues can escalate quickly.

Proper lubrication is also essential. It helps reduce friction and prolongs lifespan. Make it a habit to check lubrication levels regularly. Ensure your lubrication system is clean and efficient. Dirty systems can hinder performance and durability.

Lastly, monitor the jaw plates' operating environment. Dust and debris can cause premature wear. Consider protective measures, such as shields or covers. These can help minimize exposure to harsh conditions. Reflect on your maintenance routines. Are they effective? Regular updates can lead to significant improvements in performance.