Selecting the right Cone Crusher Concave can greatly impact your operation's efficiency. The concave is a crucial part of the cone crusher. It helps to crush materials into the desired size while ensuring optimal performance.

Understanding the material type you are processing is vital. Different materials may require specific concave designs for effective crushing. Moreover, the wear characteristics of the concave can affect its longevity. Choosing the wrong one can lead to increased costs and downtime.

There’s a lot to consider when making this decision. Sometimes, users overlook the specifics and face issues later. Investigating available options is key. A poorly chosen Cone Crusher Concave can lead to frustration. Take time to reflect on your unique needs before making a choice.

In the mining industry, the choice of cone crusher concaves is crucial. These components significantly impact the efficiency of the crushing process. Good concaves ensure even wear and optimal crushing angles. When concaves wear unevenly, it leads to poor performance. This can result in increased operational costs and downtime.

Understanding the material composition of the concaves is important. Different materials provide varying levels of durability and resistance. For instance, some concaves may wear down quickly, while others can withstand heavy loads longer. Selecting the right material based on your mining conditions matters. It’s essential to evaluate the specific needs of your operations before making a choice.

Moreover, the installation of concaves is often overlooked. Improper installation can lead to further complications. Ensuring correct alignment and snug fit is vital. Regular inspections can help identify wear patterns and potential problems early. This proactive approach can save time and resources in the long run. Remember, the right concaves can enhance productivity, but neglecting their care may lead to costly failures.

| Concave Type | Application | Material | Typical Lifespan | Benefits |

|---|---|---|---|---|

| Standard Concave | Primary Crushing | High Manganese Steel | 4-6 Weeks | Durable, good for various materials |

| Medium Concave | Secondary Crushing | Alloy Steel | 3-5 Weeks | Provides a balanced performance |

| Short Head Concave | Tertiary Crushing | Chrome-Moly Steel | 2-4 Weeks | Produces a finer product size |

| Fine Concave | Quaternary Crushing | High Carbon Steel | 3-6 Weeks | Superior control over particle size |

Choosing the right cone crusher concave is crucial for efficiency. The material of the concave directly affects the performance and lifespan of the equipment. Common materials include manganese steel and chromium alloy. Manganese has excellent wear resistance, making it popular in mining applications. Reports show that manganese concaves can have a wear life increase of up to 30%.

Another essential factor is the level of rock hardness. Softer rocks require less durable materials. In contrast, harder materials necessitate more robust concaves. It’s important to consider the specific type of material being crushed. Increased hardness may lead to faster wear rates. Industry data suggests that concaves designed for high-impact loads might require frequent inspections.

Additionally, environmental conditions play a role. If the mining area has high moisture, corrosion can occur. This can degrade the concave material's quality. Balancing longevity and performance is often a challenge. Equipment managers should assess wear patterns regularly. The choice of concave affects production efficiency and maintenance frequency, highlighting the need for careful selection.

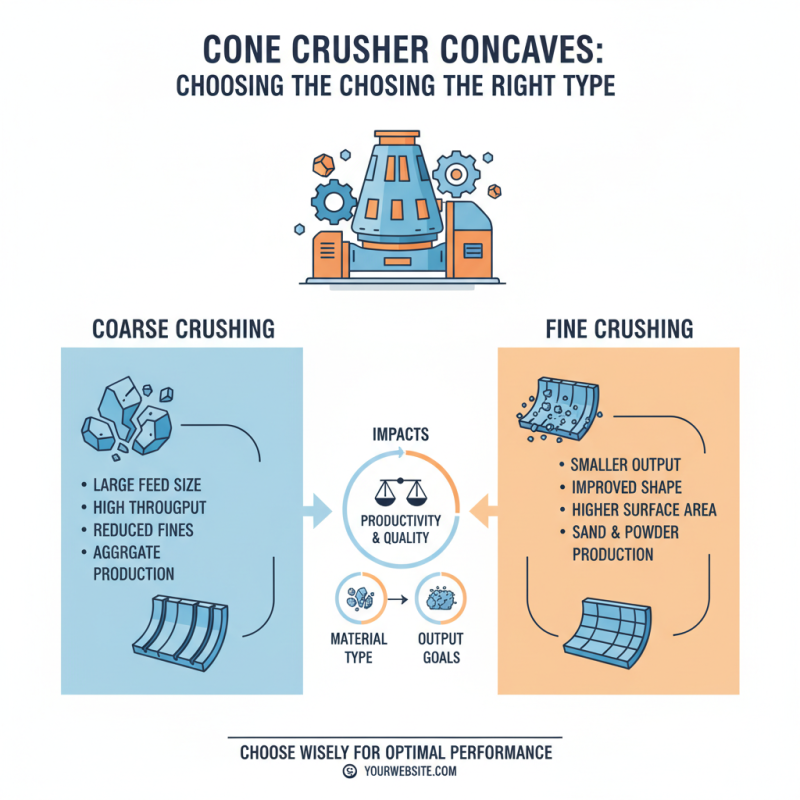

Choosing the right cone crusher concave is crucial. Different types serve various purposes. Some are designed for coarse crushing, while others suit fine crushing. This distinction affects productivity and material quality.

Conical shapes vary in design and thickness. A thicker concave provides durability but may limit the granularity of crushed material. On the other hand, a thinner design allows for finer outputs, yet may wear out quickly. It’s essential to balance these factors.

Understand your material’s characteristics. Hard materials require robust concaves. Softer materials might benefit from more delicate options. Monitoring wear patterns will also guide your choice. This process is not foolproof; missteps can lead to increased costs. Keep experimenting. Adjustments are vital for optimal operation.

Choosing the right cone crusher concave is crucial for effective operations. Assessing wear characteristics is key to making optimal selections. Different materials experience varying wear rates. This can impact productivity and equipment longevity.

One significant factor is the rock type being crushed. Harder materials can quickly wear down concaves. Consider how often you change the concave. Do you replace it too frequently? A balance between durability and performance is essential.

Tips: Pay close attention to wear patterns. Regularly inspect your concaves for signs of fatigue. Adjust your selection based on these observations. You might find that a different profile could work better for your specific needs.

Understanding the environment is also vital. Is it a humid area or a dry region? Moisture can affect the materials and wear rates. Make thoughtful choices based on your unique operational conditions. You might need to reassess your current concave selection.

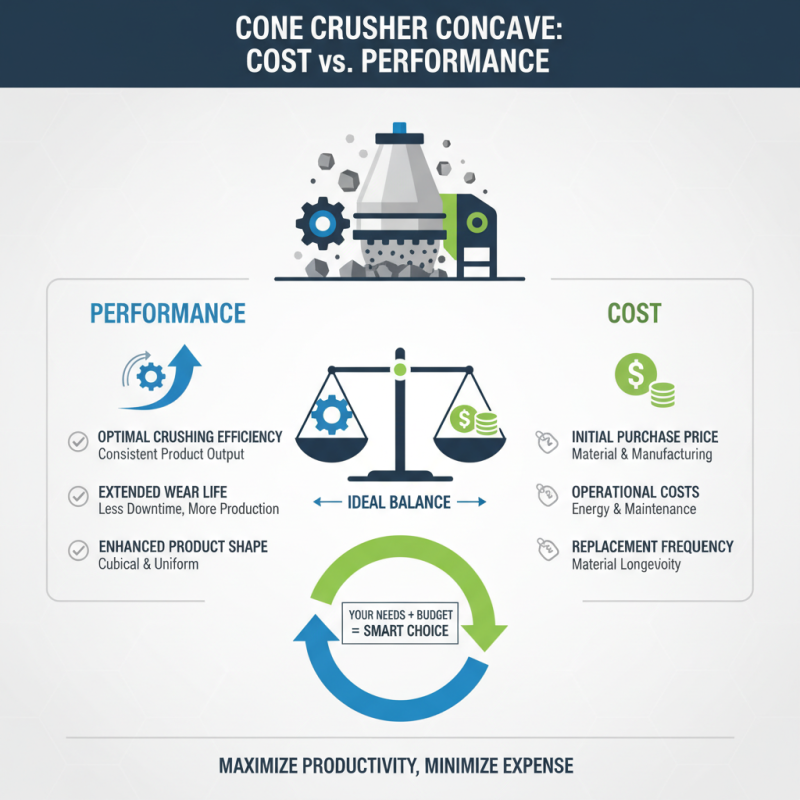

Choosing the right cone crusher concave involves balancing cost and performance. The ideal choice can significantly impact your operation. You want a concave that fits your needs without exceeding your budget. Performance is crucial, but so is cost-effectiveness. Sometimes, a cheaper option might not yield the same results.

Quality matters. A high-performance concave can increase productivity but might come at a higher price. Conversely, a lower-cost concave may wear out more quickly, leading to unexpected costs. It’s essential to evaluate your specific needs. Consider the type of material, processing demands, and output requirements.

Tips: Always check reviews and consult experts. They can provide insights into performance and longevity. Don't just focus on initial costs. Factor in long-term performance. A well-made concave can save you money over time. Lastly, think about compatibility with your existing equipment. Misalignments can lead to inefficiencies and wasted resources. Analyze these factors carefully to find the best value for your project.