In the realm of crushing equipment, selecting the appropriate jaw crusher plate material is pivotal for enhancing operational efficiency and prolonging equipment lifespan. Industry reports indicate that improper material choices can result in significant downtime and maintenance costs, which can amount to 5-10% of a company’s total operational budget. With the global demand for crushed material projected to grow at a CAGR of over 4% through 2025, understanding the implications of jaw crusher plate material becomes essential for optimizing production processes and achieving competitive advantage.

Various factors influence the selection of jaw crusher plate material, including hardness, wear resistance, and the specific application of the crusher. According to recent studies, manganese steel, for example, is favored for its high impact strength and ductility, making it suitable for hard rock crushing. Conversely, ceramic materials may be considered for their exceptional wear characteristics when dealing with softer materials. As production requirements evolve, the importance of selecting the right jaw crusher plate material will become increasingly critical, informing not only the efficiency of operations but also the overall sustainability practices within the industry. Thus, industry professionals must stay ahead of these trends to maximize their operational performance and minimize unnecessary expenditures.

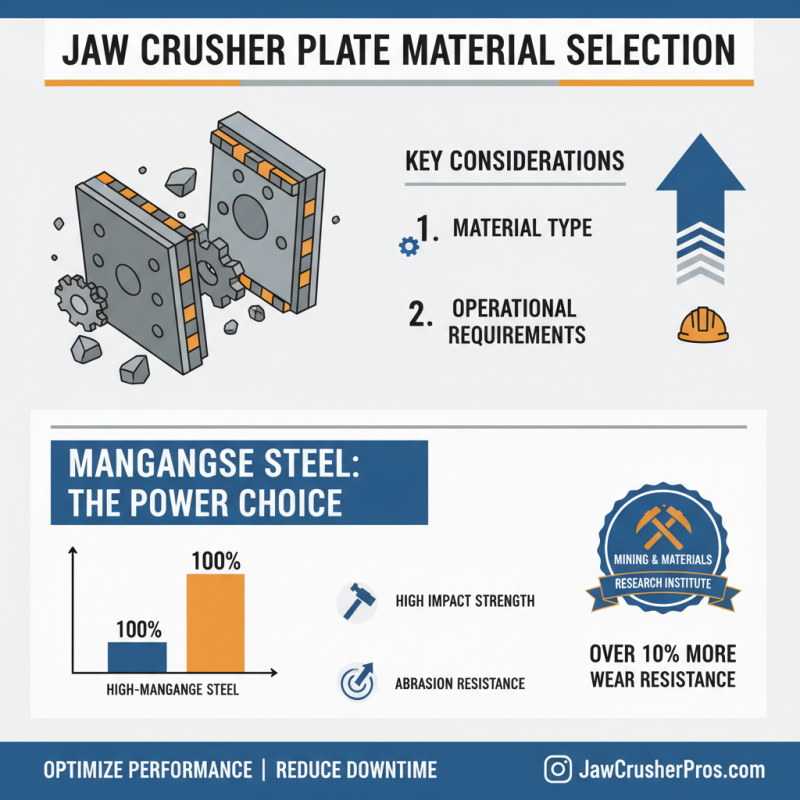

When selecting the right jaw crusher plate material, it is essential to understand the various types available, as each offers distinct advantages depending on the operational requirements. Commonly used materials include manganese steel, which is known for its high impact strength and resistance to abrasion. According to a report by the Mining and Materials Research Institute, high manganese steel can withstand over 10% more wear than standard steel plates, making it a favored choice in high-impact environments.

Another valuable option is chrome steel, which provides superior hardness and wear resistance, particularly under moderate impact conditions. A study by the International Journal of Mining Science and Technology highlights that chrome steel plates maintain structural integrity during prolonged use, often outperforming other materials in applications requiring a combination of hardness and ductility. Additionally, composite materials are gaining traction in the industry, delivering enhanced performance through a combination of properties from different elements, thus catering to specific operational challenges.

Ultimately, the selection process should consider the specific characteristics of the material, including tensile strength, hardness, and resistance to fatigue. The right choice can significantly impact the efficiency and lifespan of the jaw crusher, ensuring optimum performance in various crushing applications.

When selecting the right jaw crusher plate material for your application, several key factors play a

significant role in ensuring optimal performance and longevity. One of the most critical considerations is the hardness of the material being crushed. According to industry reports, materials with a high impact resistance, such as

manganese steel, are often preferred for their ability to withstand heavy loads and prolong the lifespan of the plates. For instance, studies have shown that optimized compositions of manganese alloys can enhance the wear resistance by up to

30%, thereby reducing downtime and maintenance costs.

Another essential factor is the operating environment. If the crusher will be used in a highly abrasive setting, incorporating specific metallurgical treatments can enhance the toughness of the jaw plates. Research indicates that jaw plates subjected to rigorous wear conditions should have a

minimum hardness of 400 HB (Brinell hardness) to prevent rapid degradation. Moreover, the operational parameters, such as the expected throughput and the type of feed materials, should also influence the choice of plate material. Notably, reports from industry analyses suggest that aligning the plate material with both the mechanical and chemical properties of the material being processed can yield efficiency improvements of

up to 25%.

In summary, choosing the correct jaw crusher plate material involves a careful evaluation of factors like

material hardness, environmental conditions, and

operational demands, which directly impact the effectiveness and durability of the equipment in the long run.

When selecting the appropriate jaw crusher plate material, a thorough understanding of the comparative analysis of durability and wear resistance in various materials is crucial. The primary factors influencing the service life and efficiency of jaw crushers are their material composition and hardness. Harder materials tend to resist wear more effectively, resulting in longer-lasting plates that maintain operational effectiveness. However, this hardness must be balanced with the material's ability to absorb impact. For instance, while high manganese steel is renowned for its excellent wear resistance, materials like alloy steel or ceramic composites may offer enhanced toughness, making them more suitable for specific applications where high impact resistance is necessary.

In addition, the environment in which the jaw crusher operates plays a significant role in determining the ideal plate material. For abrasive materials, a tough and wear-resistant plate is essential to withstand continuous grinding. Conversely, in applications with less abrasive substances, opting for a softer material can help mitigate issues related to fractures and chipping. A comprehensive analysis of the specific application requirements, including the material characteristics and operational conditions, will aid in making an informed decision. Ultimately, choosing the right jaw crusher plate material involves balancing durability, wear resistance, and operational demands to enhance performance and longevity.

When selecting the appropriate jaw crusher plate material, cost-effectiveness is a crucial consideration that can significantly impact the overall operational budget and machinery longevity. Different materials, such as manganese steel, chrome-molybdenum alloy, or ceramic composites, offer varying levels of hardness, wear resistance, and impact toughness, which directly relate to their performance and lifespan in abrasive environments. It is essential to evaluate not only the initial acquisition costs but also the expected service life and maintenance requirements of each material option.

In many cases, the cheapest material might not yield the best long-term value due to increased wear rates or the need for more frequent replacements. For instance, while wearing plates composed of high manganese steel can be more expensive initially, their excellent resistance to impacts and wear can lead to lower costs over time, as they require less frequent replacement. Therefore, conducting a thorough cost-benefit analysis that considers not only the purchase price but also the performance characteristics and lifecycle costs of each material can help businesses make informed decisions that align with their operational needs and budget constraints.

When it comes to ensuring the longevity of jaw crusher plates, maintaining optimal conditions is crucial. The first step in effective maintenance practices involves regular inspections to identify wear patterns. By monitoring the surface of the plates, operators can detect areas that require attention before extensive damage occurs. Cleaning the plates routinely to prevent material buildup also plays a vital role in maintaining performance and extending their lifespan. Consistent checks on the alignment and tightening of bolts during maintenance sessions help in preventing premature wear caused by uneven pressure distribution.

Additionally, choosing the right maintenance interval is essential. Regularly scheduled maintenance, rather than waiting for obvious signs of wear, can drastically improve the service life of the plates. Implementing a lubrication regimen tailored to the specific environment of the operation helps reduce friction and wear, further prolonging plate lifespan. Operators should also be mindful of how the crusher is loaded; avoiding overload can prevent excessive stress on the plates and aid in maintaining their integrity. Through strategic maintenance practices and awareness of operational conditions, users can significantly enhance the durability and efficiency of their jaw crusher plates.

| Material Type | Hardness (Brinell) | Tensile Strength (MPa) | Weight (kg) | Estimated Lifespan (hours) | Maintenance Frequency (weeks) |

|---|---|---|---|---|---|

| MN13 | 220 | 780 | 150 | 800 | 4 |

| MN18 | 230 | 850 | 160 | 700 | 6 |

| Chrome Molybdenum (Cr-Mo) | 200 | 700 | 170 | 750 | 5 |

| High Carbon Steel | 250 | 900 | 140 | 600 | 3 |

| Alloy Steel | 240 | 800 | 155 | 700 | 4 |