Cone crusher is vital in mining and construction. The Cone Crusher Concave plays a crucial role in this process. It is the part that crushes the material as it moves through the machine.

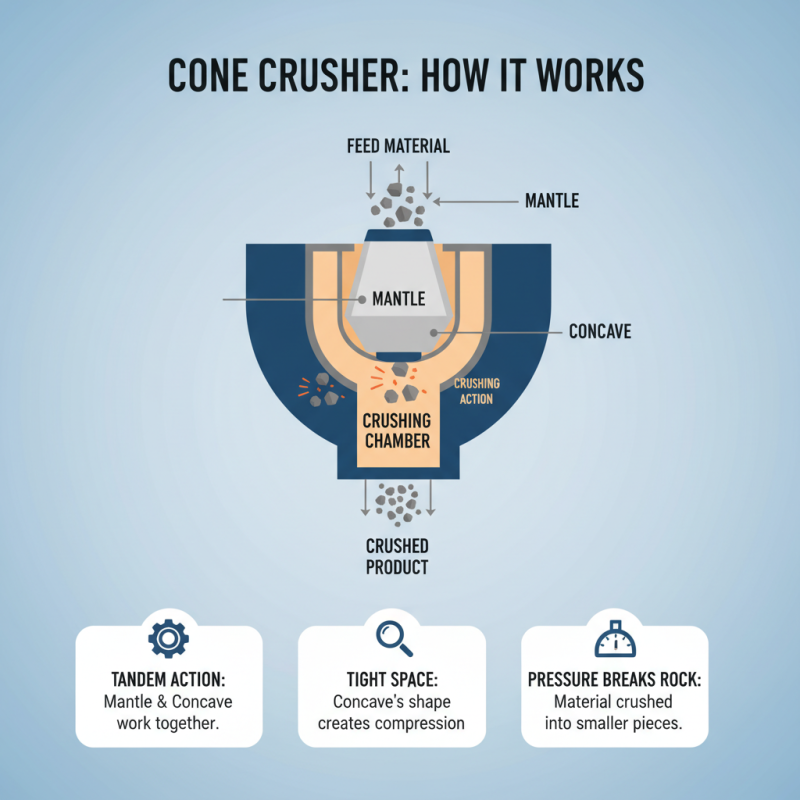

Understanding how the Cone Crusher Concave works is essential for efficient operations. This component is shaped like a bowl and sits inside the crusher’s main housing. When rocks enter the crusher, the concave compresses them against a moving cone. This action breaks the rocks into smaller pieces.

Several factors can affect the performance of the Cone Crusher Concave. Wear and tear are inevitable, leading to reduced efficiency. Operators must regularly check for signs of damage. Selecting the right materials and maintaining them properly can help. Attention to these details can improve lifespan and functionality. Exploring the intricacies of the Cone Crusher Concave reveals both its effectiveness and the challenges faced in its use.

A cone crusher concave is a crucial component in cone crushers. It is the part that crushes the material during the crushing process. The concave is usually made from high-quality steel, reinforced for durability. As the raw material enters the crusher, it sits between the concave and the mantle. This design allows for efficient crushing and shaping of the material.

The working principle is straightforward: the cone crusher's motor drives the eccentric shaft. This movement forces the mantle closer to and further from the concave. The space between them compresses the material. Smaller pieces fall through, while larger ones are crushed further. However, the wear on the concave is significant. Over time, it can lose its effectiveness, which may require replacements sooner than expected. Regular inspections can help, but wear and tear are inevitable.

Understanding the cone crusher concave's importance is essential for efficient operations. A well-maintained concave ensures optimal performance. Neglecting this component might result in poor crushing efficiency and increased operational costs. Monitoring wear rates can lead to more informed decisions about maintenance and replacement. This proactive approach can minimize downtime.

| Dimension | Specification | Material | Weight (kg) |

|---|---|---|---|

| Standard Concave | C2 | Manganese Steel | 250 |

| Medium Concave | C3 | Manganese Steel | 280 |

| Short Head Concave | C4 | Manganese Steel | 300 |

| Extra Coarse Concave | C5 | Manganese Steel | 320 |

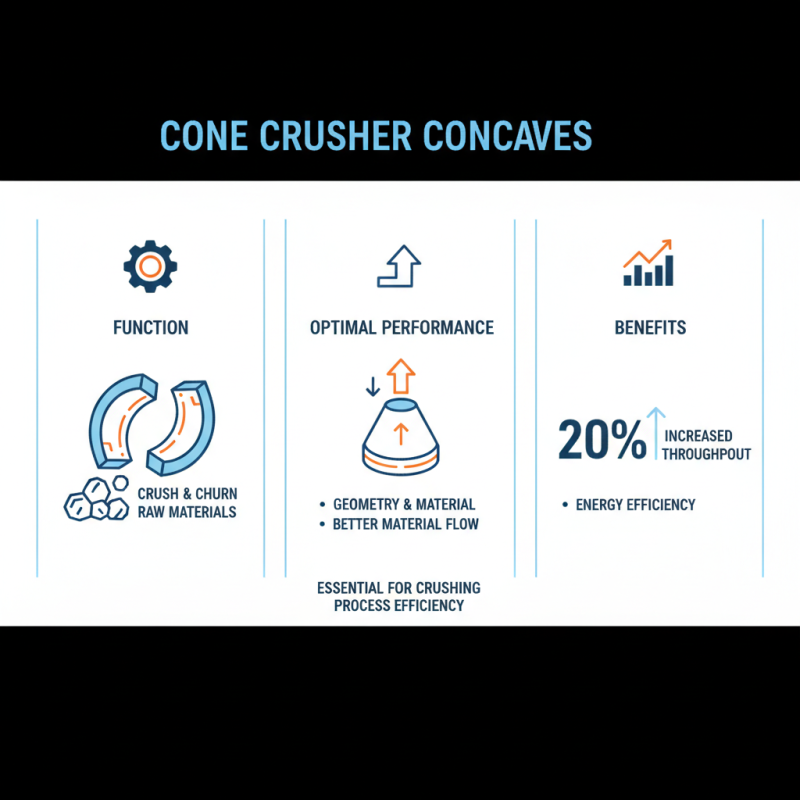

Cone crusher concaves are essential components in the crushing process. They are designed to crush and churn raw materials into smaller sizes. The geometry and material composition of concaves are crucial for optimal performance. Research indicates that well-designed concaves can increase throughput by up to 20%. Correctly shaped concaves lead to better material flow and energy efficiency.

The purpose of cone crusher concaves extends beyond mere crushing. They also ensure a balanced distribution of forces during operation. Optimal concave design can reduce wear rates, extending the life of both the concaves and the entire machine. Studies show that an average increase of 15% in lifespan can be achieved with proper materials and designs. However, some manufacturers still overlook the importance of periodic design evaluation, leading to inefficiencies and unnecessary costs.

In practice, not all designs meet operational needs. There are instances where concave configurations cause blockages or uneven wear. This situation results in higher maintenance costs and downtime. Continuous innovation is vital to address these challenges. The industry trends indicate a pressing need for tailored solutions that fit specific application demands. Feedback loops between operators and designers can improve concave effectiveness significantly.

Cone crusher concaves are essential components in the crushing process. They work in tandem with the mantle to crush rocks and minerals. The concave's shape allows it to create a tight space for the material. When rocks enter, they are compressed between the concave and the mantle. This pressure breaks down the material into smaller pieces.

In crushing operations, concaves can wear out over time. Factors like the hardness of rocks and operational conditions affect their lifespan. Regular inspection is necessary to prevent unexpected downtime. Operators must find a balance between the performance of the concaves and their wear rate. Not all concaves perform equally well for every type of material. It may take time to identify the optimal choices for different tasks.

Understanding the mechanics of cone crusher concaves is vital. They play a crucial role in achieving efficient crushing. Proper maintenance and selection can enhance productivity. It’s a challenge that requires constant attention. Mistakes can lead to inefficiencies, so continuous learning is essential in this process.

Cone crusher concaves play a crucial role in material processing. Understanding the materials used in manufacturing these components can enhance their efficiency and lifespan. Typically, concaves are made from manganese steel. This material offers high impact strength and good resistance to abrasion. It is crucial for high-performance crushing.

Another material often used is alloy steel, which includes chrome and nickel. Alloy steel enhances toughness, allowing the concaves to withstand harsh conditions during operation. Data shows that manganese steel concaves can last up to 40% longer than standard grades under similar conditions. However, wear rates can vary based on the type of rocks being crushed.

Furthermore, some manufacturers are exploring ceramic matrix composites. These materials offer remarkable hardness and very low wear. Though they are more expensive, their durability can offset costs in the long run. Early data from industry reports indicates that using advanced materials could lead to better efficiency and energy savings in operations. Experimentation is key to finding the optimal material blend. While innovations promise better results, not all have been thoroughly tested in the field. It creates a pressing need for ongoing research and optimization.

Maintaining cone crusher concaves is crucial for efficient operation. These parts are subjected to considerable wear and tear. Regular inspection is essential. Check for signs of wear, cracks, or deformation. Ignoring these signs can lead to larger problems. The lifespan of the concave can be significantly reduced if not monitored properly.

Cleaning the concave regularly is important. Accumulated debris can lead to poor performance. Use proper cleaning methods to avoid damage. Inspecting and replacing worn liners helps prevent material losses. Keeping an eye on the concave's fit can also prevent excessive wear. Misalignment is a common issue that can go unnoticed.

It’s wise to keep a maintenance log. This can help identify patterns in wear and allow for proactive measures. Skipping maintenance tasks might save time now, but it will lead to bigger issues later. Additionally, training operators on proper use reduces unnecessary strain on the concave. Regular maintenance pays off in the long run.