In the realm of mineral processing, the efficiency and effectiveness of crushing operations are paramount, and one of the key components that significantly influences these processes is the Cone Crusher Concave. According to industry reports, such as those from the Mining Equipment Market Analysis, the global cone crusher market was valued at over $1.5 billion in 2021, with projections indicating a compound annual growth rate (CAGR) of 4.5% through 2028. The Cone Crusher Concave plays a critical role in the optimization of size reduction, directly affecting the overall throughput and efficiency of the crushing process. Its design and material composition are crucial in achieving the desired product size while maximizing the destruction of ore. As mining and aggregate industries continue to evolve, understanding the intricacies of Cone Crusher Concaves will be vital for operators looking to enhance their operations and maintain a competitive edge in a rapidly changing market.

Cone crusher concaves play a vital role in enhancing material crushing efficiency, impacting production rates and overall operational costs. According to a report by Research and Markets, the global mining equipment market is expected to grow at a CAGR of 6.2% from 2021 to 2026, highlighting the increasing reliance on efficient crushing systems. The design and material composition of concaves significantly influence the crushing process, particularly in achieving optimal reduction ratios and particle shapes. High-quality concaves not only improve crushing efficiency but also extend the lifespan of the crusher, leading to reduced downtime and maintenance costs.

The efficiency of cone crushers is determined by various factors, with concave geometry being a critical parameter. A study published in the Journal of Engineering Research indicates that the right profile can enhance the material throughput by up to 25%. Additionally, the use of advanced materials such as alloy steel or manganese can further maximize wear resistance, allowing for consistent performance over time. As mining operations continue to optimize their processes, the importance of innovation in cone crusher concaves cannot be understated, as it directly correlates to productivity and cost-effectiveness in material processing.

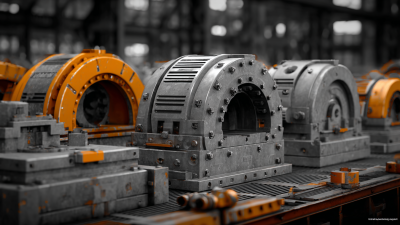

Cone crusher concaves are a crucial design feature that significantly influences the efficiency of material processing in mining and construction industries. These concaves, located within the cone crusher, are responsible for creating the compressive force required to crush various types of materials. Their design is meticulously crafted to enhance the crushing efficiency while also promoting effective material flow. The optimal shape and surface profile of concaves can lead to reduced energy consumption and minimized wear, ultimately contributing to lower operational costs.

Cone crusher concaves are a crucial design feature that significantly influences the efficiency of material processing in mining and construction industries. These concaves, located within the cone crusher, are responsible for creating the compressive force required to crush various types of materials. Their design is meticulously crafted to enhance the crushing efficiency while also promoting effective material flow. The optimal shape and surface profile of concaves can lead to reduced energy consumption and minimized wear, ultimately contributing to lower operational costs.

Furthermore, the materials used in fabricating cone crusher concaves play a pivotal role in their performance. High-manganese steel is commonly employed due to its excellent wear resistance and ability to withstand the forces exerted during the crushing process. Additionally, innovative designs, such as the inclusion of a curved profile, allow for better material handling and improved throughput. By understanding these design features, industries can select the appropriate cone crusher concaves that align with their specific processing requirements, thereby maximizing productivity and ensuring more efficient operations.

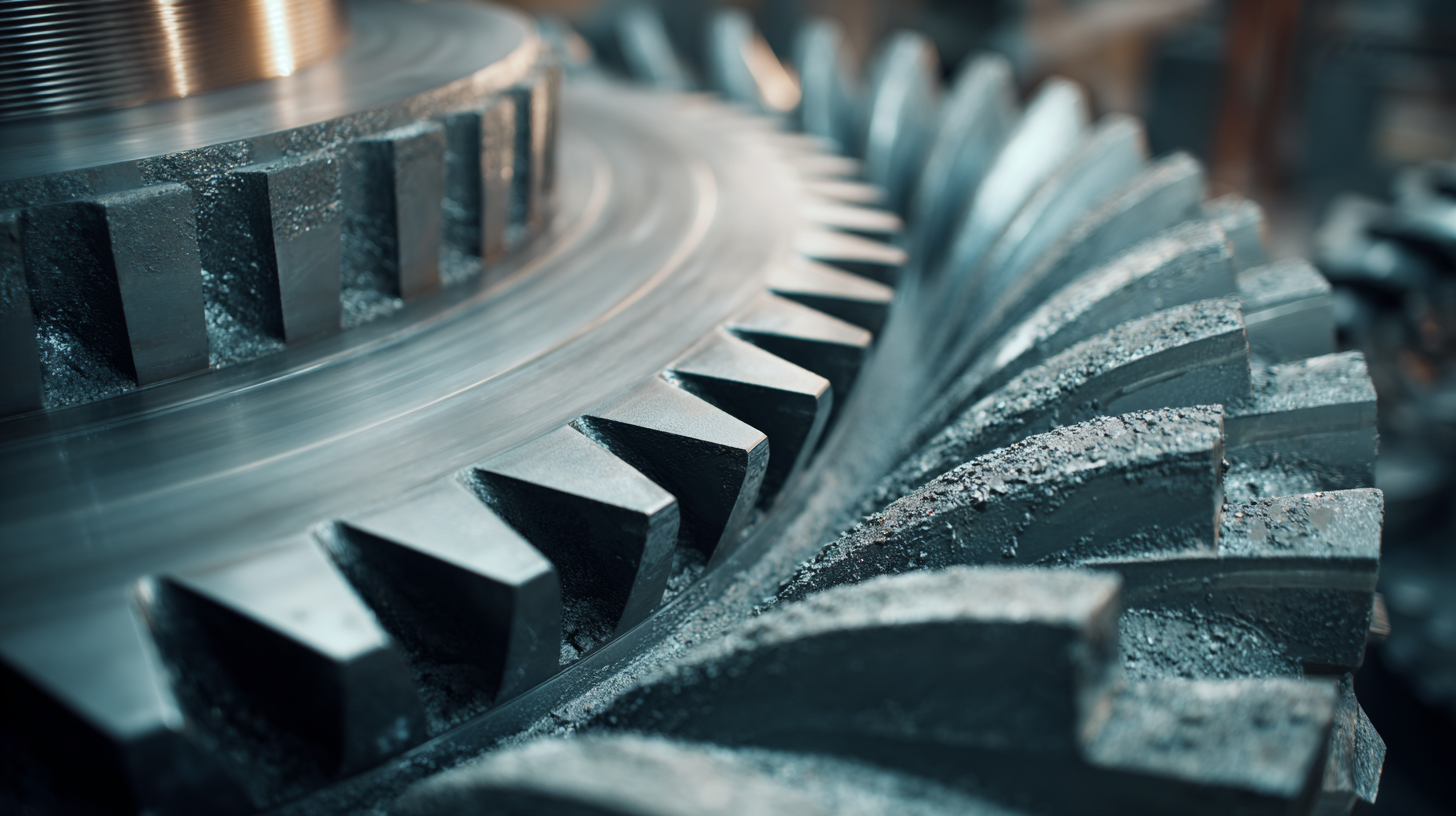

The geometry of cone crusher concaves plays a critical role in the efficiency of material processing. Concaves are designed to create a narrow gap between the mantle and the concave surface, effectively determining the size of the crushed material. This gap, influenced by the concave curvature and depth, allows for controlled size reduction as material passes through. A well-designed concave geometry enhances the crushing action, enabling the crusher to achieve the desired particle size with minimal energy consumption.

Different concave profiles can be employed to cater to specific material challenges. For instance, a steeper concave angle can improve the retention time of the material, leading to more effective size reduction. Conversely, a flatter shape can facilitate a smoother throughput for softer materials. The choice of concave geometry not only impacts the size of the output material but also influences wear patterns and overall equipment longevity. Understanding these geometric relationships is essential for optimizing crushing processes and achieving operational efficiency.

Maintaining cone crusher concaves is crucial for ensuring optimal performance and longevity in material processing. According to a report by the Mining and Materials Processing Institute, proper maintenance can extend the life of concaves by up to 30%, translating to significant cost savings for operators. Regular inspection and timely replacement of worn concaves not only prevent equipment failure but also enhance the overall efficiency of the crushing process.

Maintaining cone crusher concaves is crucial for ensuring optimal performance and longevity in material processing. According to a report by the Mining and Materials Processing Institute, proper maintenance can extend the life of concaves by up to 30%, translating to significant cost savings for operators. Regular inspection and timely replacement of worn concaves not only prevent equipment failure but also enhance the overall efficiency of the crushing process.

Tips: Always conduct routine checks every 500 operating hours. Look for signs of wear or damage, as addressing these early can prevent more significant issues down the line.

Another aspect of concave maintenance is the correct selection of materials. Data from the International Journal of Mining Science and Technology emphasizes that using high-quality manganese steel concaves can significantly improve wear resistance and life expectancy. These materials can withstand heavier loads and resist the abrasive nature of crushed materials, making them a wise investment for long-term operational success.

Tips: Consider using a mix of concave profiles to accommodate various material sizes and hardness. This strategy can optimize your crusher's capabilities and enhance material throughput.

The effectiveness of cone crusher concaves plays a crucial role in enhancing operational performance within material processing. By ensuring optimal design and material quality, these components can significantly impact the efficiency of the crushing process. A well-optimized concave not only maximizes the crushing capacity but also leads to a more uniform product size, which is essential for downstream processing.

Recent initiatives in various operations highlight the importance of minimizing downtime, particularly concerning liner replacement. For instance, the improvements implemented at a mining site in South Africa have successfully reduced the duration for changing out crusher liners while simultaneously enhancing safety measures. This change demonstrates the direct relationship between the operational performance of cone crushers and the effective use of concaves, emphasizing the need for advancements in both technology and maintenance practices to maximize productivity.