The Cone Crusher Mantle is crucial in the crushing process of various materials, including rocks and minerals. This component shapes the flow of material, ensuring efficient size reduction. According to a report by the Mining Equipment Technology Association, more than 60% of crushing efficiency relies on the design and integrity of the mantle.

Industry expert John Smith stated, "The Cone Crusher Mantle is the heart of the machine." His insight highlights its essential role in performance. While advances in mantle materials have improved durability, challenges remain. For instance, uneven wear can lead to operational inefficiencies.

Optimizing the Cone Crusher Mantle requires ongoing assessment and innovative solutions. Manufacturers must address wear patterns and material fatigue. To enhance productivity, understanding these factors is vital for modern crushing operations. Balancing design with practical application continues to be an industry pursuit.

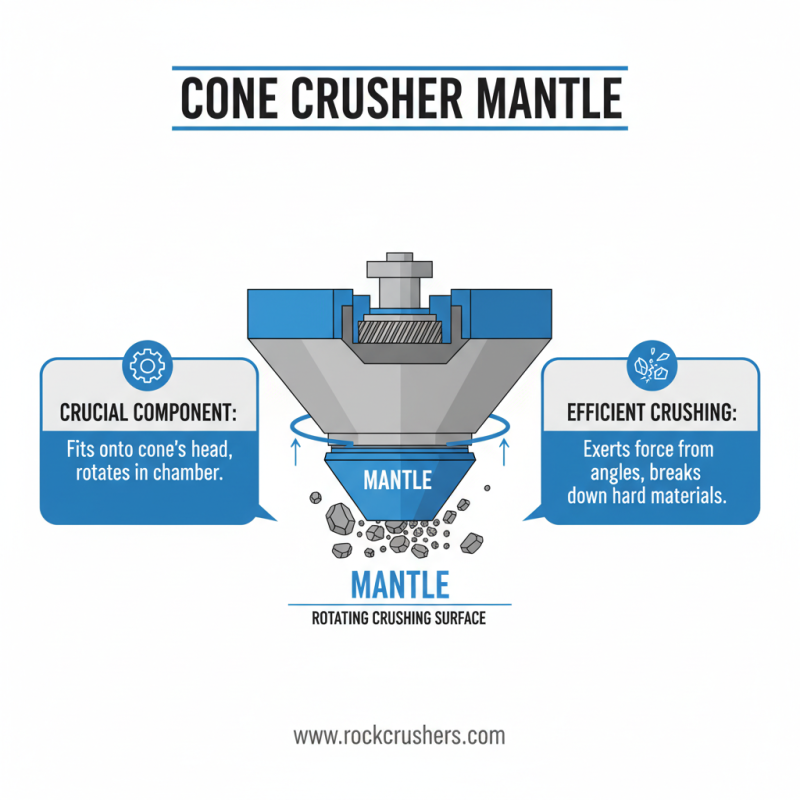

A cone crusher mantle is a crucial component in the cone crushing process. It is a heavy-duty piece that fits onto the cone’s head. The mantle rotates within the crushing chamber to crush rocks and minerals. Its design allows it to exert force on materials from various angles. This unique shape helps break down even hard materials into smaller, manageable pieces.

The role of the mantle in crushing is both vital and intricate. As it wears down, the efficiency drops. A worn mantle can cause more harm than good. It may lead to uneven crushing and an increase in energy consumption. Operators must regularly inspect and replace this part to maintain optimal performance. A simple oversight can result in costly downtime.

When selecting a mantle, it’s important to consider various factors. The material of the mantle influences its lifespan and effectiveness. Choices are often a balance between durability and performance. Sometimes, finding the ideal mantle is trial-and-error. This process can be frustrating but is essential for optimal operation.

The cone crusher mantle is a crucial component in the crushing process. Its main role is to crush materials by applying pressure. The mantle fits over the cone and moves with it. This motion creates a gap that reduces the size of rocks. The design allows for efficient crushing. However, the shape is sometimes not perfect. It might wear unevenly over time, leading to less efficient performance.

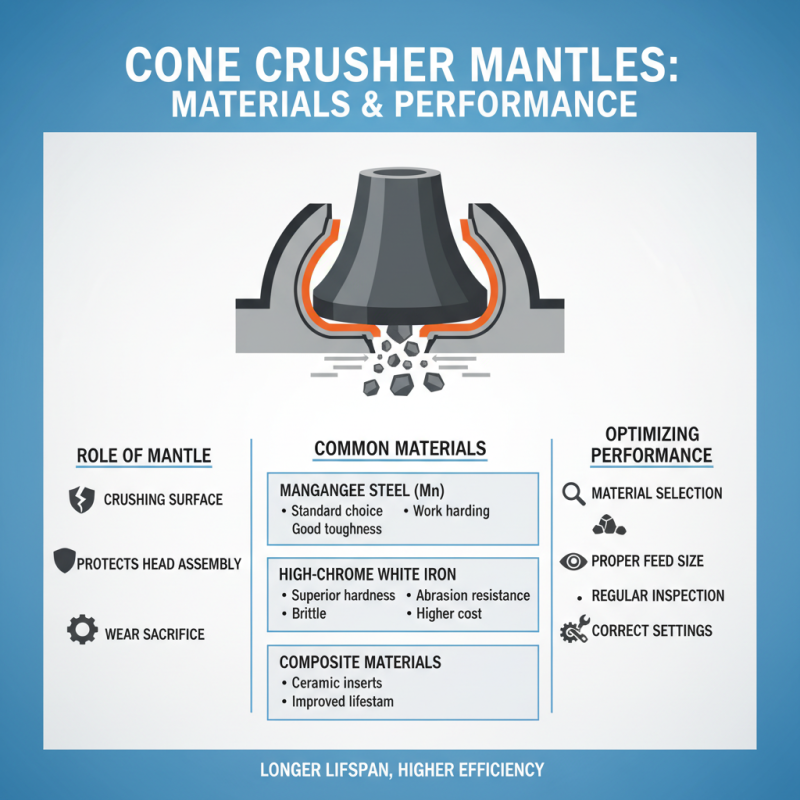

Constructed from resilient materials, the mantle features a robust outer layer. This can often be manganese steel or other alloys that enhance durability. The inner structure is usually engineered for optimal fitting. Over time, as the mantle wears, its shape can change. This can affect productivity and increase costs. Regular inspection of the mantle is essential. Small cracks or excessive wear must be addressed to avoid larger problems.

The composition of the mantle affects its lifespan and performance. A well-designed mantle can withstand significant pressure. Soft or poorly mixed materials may lead to early failure. The balance of hardness and ductility is vital. Some mantles perform well under harsh conditions, while others may not. Understanding these nuances can drive better operational decisions.

The cone crusher mantle plays a critical role in the crushing process. This component sits atop the cone crusher and is responsible for compressing materials. As the mantle moves, it creates a crushing action against the stationary bowl. This interaction is vital for reducing large materials into smaller, usable sizes.

In operation, the mantle’s design allows it to withstand high temperatures and extreme wear. It continuously lifts and drops, facilitating the crushing cycle. However, over time, wear can impact performance. Regular inspections are essential to identify signs of wear. Replacement of the mantle can prevent material buildup and reduce efficiency.

When the mantle is not working optimally, it can lead to uneven product size. This inconsistency can affect the entire crushing operation. Proper maintenance is necessary to keep the mantle functional. Operators must pay attention to its condition during routine checks. This will ensure the crushing process remains efficient and effective. Careful management of the cone crusher mantle contributes to overall productivity in the crushing industry.

This bar chart illustrates the efficiency of the cone crusher mantle over different materials based on the crushing process. The performance is measured by the percentage of output size distribution achieved after crushing various material types.

Cone crusher mantles play a vital role in the crushing process of various materials. The mantle, which is a crucial component of the cone crusher, is responsible for crushing the rock against the concave surface. Understanding the materials used for these mantles can help optimize their performance and lifespan.

Common materials for cone crusher mantles include manganese steel, chrome-moly steel, and alloyed metals. Manganese steel is widely used due to its excellent hardness and wear resistance. Studies show that it can withstand extreme conditions and resist deformation under stress, promising up to 14% to 24% manganese content. Chrome-moly steel, on the other hand, is popular for its impact resistance and toughness, often used in high-impact environments.

Additives like tungsten or vanadium may be blended for enhanced durability. However, the choice of material should reflect the specific crushing task. This often requires careful analysis of rock types and desired output. Overlooking the right material can lead to premature failure or inefficiencies. Thus, understanding material properties is not just beneficial; it’s essential for enduring performance in tough operational settings.

Maintaining a cone crusher mantle is crucial for optimal performance. The mantle is a key wear part. It directly interacts with the rocks being crushed. Regular inspection can reveal wear issues early. This prevents unexpected downtime. Operators should check for signs of wear and deformation.

Cleaning the area around the mantle is important. Debris can cause excess wear. Ensure that the sealing system is intact. Leaks can lead to oil contamination. This will affect both performance and longevity. Operators often overlook these small details. Regular maintenance can save costs in the long run.

Keep an eye on the mantle's temperature. Overheating can indicate other problems. It might be worth considering different materials for replacement. Some options may offer better durability. Always track the performance metrics. If something feels off, investigate it further. Ignoring these signs can lead to larger issues down the road.

| Dimension | Value |

|---|---|

| Cone Crusher Type | Standard |

| Mantle Diameter | 60 inches |

| Weight | 1,500 lbs |

| Material | High Manganese Steel |

| Typical Lifespan | 2,000-3,000 hours |

| Replacement Frequency | Every 6-12 months |

| Common Issues | Wear, Damage from Hard Material |

| Maintenance Tips | Regular Inspections, Proper Lubrication |