Proper maintenance of cone crusher parts is vital for ensuring optimal performance and prolonging their lifespan.

According to industry reports, the cost of replacing worn-out components can account for up to 30% of the total operational costs of a crushing plant, emphasizing the importance of effective upkeep.

Regular inspections and timely servicing can significantly reduce equipment failures and extend the life of these critical components.

Research indicates that implementing a robust maintenance program can increase the lifecycle of cone crusher parts by up to 50%, resulting in higher productivity and reduced downtime.

By understanding the best practices for maintaining these essential parts, operators can maximize their investment and ensure that their crushing operations run smoothly and efficiently.

Proper maintenance of cone crusher parts is vital for ensuring optimal performance and prolonging their lifespan.

According to industry reports, the cost of replacing worn-out components can account for up to 30% of the total operational costs of a crushing plant, emphasizing the importance of effective upkeep.

Regular inspections and timely servicing can significantly reduce equipment failures and extend the life of these critical components.

Research indicates that implementing a robust maintenance program can increase the lifecycle of cone crusher parts by up to 50%, resulting in higher productivity and reduced downtime.

By understanding the best practices for maintaining these essential parts, operators can maximize their investment and ensure that their crushing operations run smoothly and efficiently.

Regular maintenance of cone crusher parts is essential for ensuring optimal performance and longevity. Neglecting routine inspections and care can lead to decreased efficiency and, ultimately, costly repairs or replacement. By regularly monitoring wear and tear, operators can address potential issues before they evolve into significant problems. This proactive approach not only enhances the operational lifespan of individual components but also maximizes the overall productivity of the crusher.

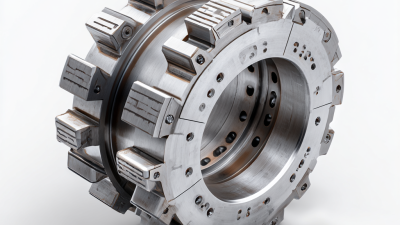

Understanding the importance of scheduled maintenance involves recognizing the critical role that each part plays in the crushing process. Key components, such as the mantle and concave, require periodic checks for wear patterns and lubrication needs. Implementing a rigorous maintenance schedule helps in identifying any irregularities early, reducing unplanned downtime. Furthermore, adhering to manufacturer guidelines and utilizing quality replacement parts ensures that the cone crusher operates smoothly and efficiently, maintaining its crucial role in production.

To enhance the lifespan of cone crusher parts, implementing key maintenance practices is essential. One of the primary methods is proper work hardening, which can significantly improve the durability of the cone liners. This process involves the gradual building up of a tough outer layer that increases resistance to wear and tear. Additionally, maintaining consistent choke feeding is crucial; it ensures that the crusher operates at optimal efficiency by reducing the likelihood of excessive wear caused by uneven feeding patterns. These practices not only extend the life of components but also improve overall crushing efficiency and product output.

To enhance the lifespan of cone crusher parts, implementing key maintenance practices is essential. One of the primary methods is proper work hardening, which can significantly improve the durability of the cone liners. This process involves the gradual building up of a tough outer layer that increases resistance to wear and tear. Additionally, maintaining consistent choke feeding is crucial; it ensures that the crusher operates at optimal efficiency by reducing the likelihood of excessive wear caused by uneven feeding patterns. These practices not only extend the life of components but also improve overall crushing efficiency and product output.

Another critical aspect is understanding the specific application parameters of the cone crusher. By recognizing the design limitations and operational settings, operators can adjust their approach to maximize performance. For instance, ensuring that the maximum feed size does not exceed 80 percent of the gape and width opening allows for better material flow and reduces stress on the equipment. Regular monitoring and adjustments based on these parameters can lead to a more efficient crushing process, ultimately prolonging the life of the machine's parts.

Identifying common wear patterns in cone crusher components is crucial for maintaining their efficiency and extending their lifespan. Cone crushers, known for their high productivity, often experience wear due to the constant friction and compression exerted during crushing operations. Reports indicate that liner wear accounts for approximately 20-30% of operational downtime in these machines. Common wear patterns include uneven wear on the mantle and concave, which can lead to poor crushing performance and increased energy consumption.

To mitigate these issues, operators should conduct regular inspections of the cone crusher components. Look for signs of abnormal wear like excessive grooves or flat spots on the liners, as these can indicate misalignment or incorrect operating parameters. Early detection of these wear patterns allows for timely adjustments or replacements, ultimately reducing downtime and maintenance costs.

**Tips:** To enhance the longevity of your cone crusher parts, consider implementing a scheduled maintenance routine that includes monitoring the wear patterns closely. Additionally, investing in quality materials for liner replacements can significantly reduce wear rates. Always ensure proper crusher settings are maintained to alleviate unnecessary strain on the components, helping to keep your operations running smoothly and efficiently.

Proper lubrication techniques are crucial for maintaining the longevity and optimal performance of cone crusher parts. According to a report by the International Journal of Mining Science and Technology, inadequate lubrication can significantly reduce the lifespan of wear parts, increasing operational costs by up to 30%. This highlights the need for a systematic lubrication schedule that adheres to the manufacturer's specifications to ensure every moving part operates smoothly, reducing friction and wear.

Utilizing high-quality lubricants specifically designed for heavy machinery can vastly improve performance. Studies indicate that synthetic oils, with their superior thermal stability and oxidation resistance, can extend the service life of hydraulic and lubrication systems by up to 50% compared to conventional oils. Additionally, implementing automatic lubrication systems can ensure consistent oil delivery, minimizing the risk of human error and maintaining optimal viscosity even in harsh operational environments. By focusing on these effective lubrication strategies, operators can not only enhance the functionality of their cone crushers but also achieve significant cost savings in the long run.

| Part Name | Recommended Lubrication Type | Lubrication Frequency (Hours) | Expected Lifespan (Years) | Maintenance Notes |

|---|---|---|---|---|

| Main Shaft | High-Viscosity Oil | 500 | 5 | Check seals for wear. |

| Eccentric Shaft | Lithium Complex Grease | 250 | 4 | Ensure proper alignment. |

| Mantle | Synthetic Oil | 300 | 3 | Regularly inspect for damage. |

| Bowl Liner | Graphite-based Grease | 400 | 4 | Monitor for wear patterns. |

| Hydraulic Cylinder | Hydraulic Oil | 500 | 7 | Check fluid levels regularly. |

To ensure the longevity of your cone crusher parts, scheduling regular inspections and replacements is crucial. By proactively maintaining your equipment, you can significantly reduce the risk of major failures that could halt operations and lead to costly downtimes. Developing a maintenance schedule tailored to the specific demands of your equipment and workload allows you to stay ahead of potential issues.

**Tips for Effective Maintenance:**

- **Regular Inspections:** Conduct thorough inspections at regular intervals to spot wear and tear early. Pay close attention to critical components like the mantle and concave, as these parts are subject to the highest levels of stress.

- **Timely Replacements:** Keep track of the lifespan of your parts and replace them proactively before they fail. This can be facilitated through a data tracking system that alerts you when it's time for a change.

- **Utilize Predictive Maintenance Technologies:** Consider incorporating AI-driven predictive maintenance solutions to analyze equipment performance. These tools can forecast failures, allowing you to manage repairs and replacements based on actual condition rather than estimations.

By adhering to these practices, you can enhance the reliability of your cone crusher while minimizing operational disruptions.