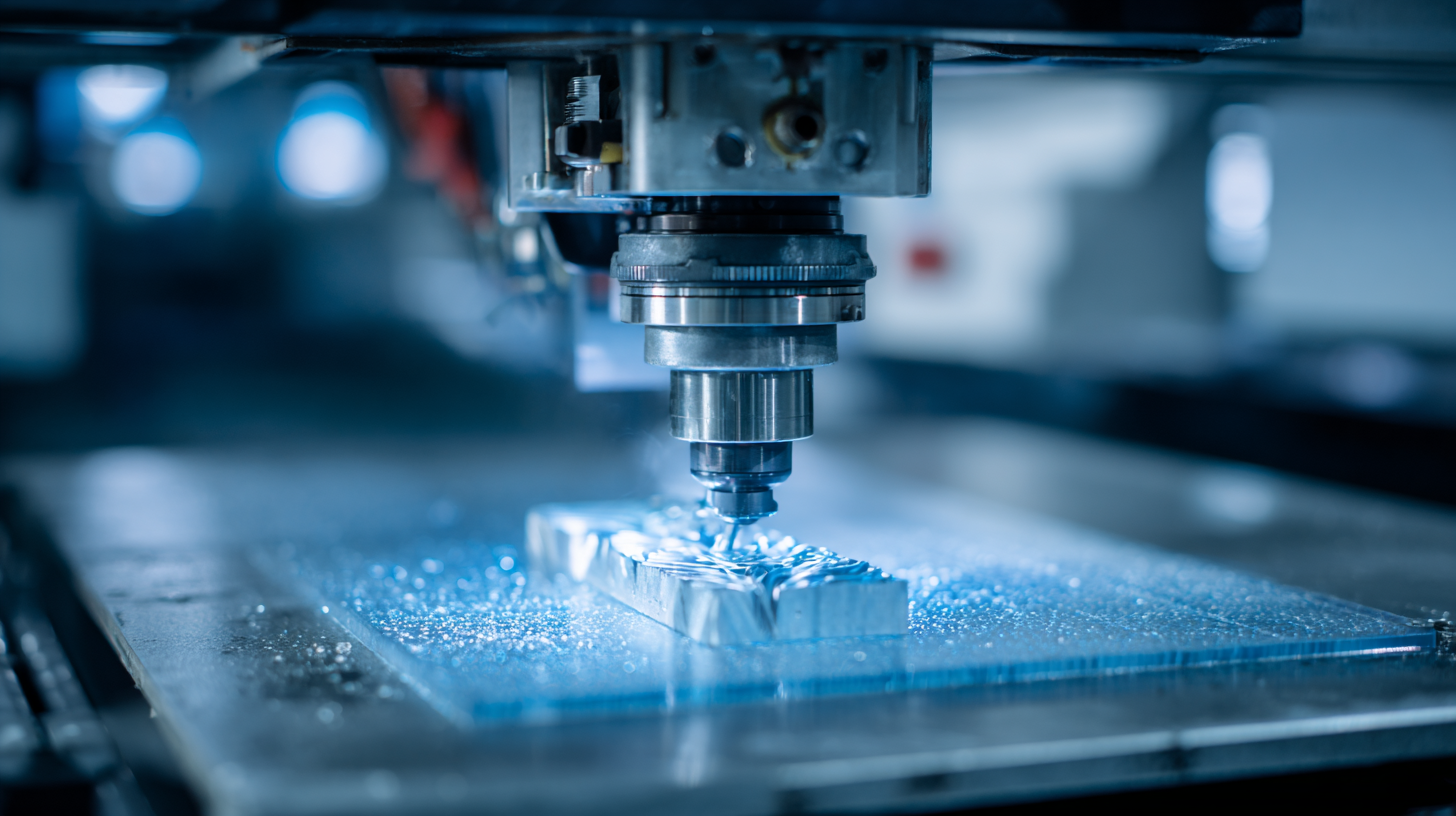

In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies plays a pivotal role in enhancing productivity and precision. One such innovation is the Fixed Jaw technology, which has emerged as a cornerstone in the realm of mechanical engineering and fabrication processes. This technology offers a multitude of benefits, including improved stability and consistency during machining operations, which in turn leads to higher quality outputs and reduced waste.

As manufacturers strive to meet the increasing demands for efficiency and accuracy, understanding the significance of Fixed Jaw systems becomes crucial. This comprehensive overview will delve into the functionalities, advantages, and best practices associated with Fixed Jaw technology, illuminating its essential role in contemporary manufacturing practices and guiding practitioners on how to effectively implement this technology in their operations.

The evolution of fixed jaw technology has played a pivotal role in modern manufacturing, particularly in the fields of precision engineering and robotics. This technology has undergone significant advancements from the traditional fixed jaw designs to sophisticated, adaptive systems that utilize a combination of robotics and AI-driven mechanisms. According to a report by the International Federation of Robotics, the global market for industrial robots reached approximately $43 billion in 2020, underscoring the increasing reliance on automation in manufacturing where fixed jaw technology is intricately involved.

Innovations in fixed jaw technology have enhanced the efficiency and precision of machining processes. The integration of advanced materials and engineering techniques has allowed for the development of jaws that can withstand greater forces while maintaining accuracy. A case study published in the Journal of Manufacturing Science and Engineering noted that utilizing advanced fixed jaw systems resulted in a 25% increase in productivity and a 30% reduction in operational costs for companies adopting these technologies. This evolution is not only reshaping manufacturing capabilities but also setting new standards for quality and reliability in production workflows.

Fixed jaw technology has become a cornerstone of modern manufacturing, significantly enhancing production efficiency and accuracy. One of the key benefits of implementing fixed jaw systems in production lines is the improved consistency in product quality. By securely holding parts in place during machining or assembly, fixed jaws minimize the risk of movement and misalignment, ensuring that components are produced to precise specifications. This reliability is crucial in industries where tolerances are minimal, thus reducing waste and rework.

Another prominent advantage of fixed jaw systems is their adaptability to various manufacturing processes. These systems can be easily customized to accommodate different workpieces, which allows manufacturers to optimize their production lines for diverse product ranges. Moreover, the robust nature of fixed jaws contributes to increased uptime and lower maintenance costs, as they are less prone to wear and deformation compared to traditional clamping methods. Ultimately, the integration of fixed jaw technology not only streamlines operations but also empowers manufacturers to respond swiftly to market demands while maintaining high standards of quality and efficiency.

| Key Benefits | Description | Impact on Production |

|---|---|---|

| Increased Precision | Fixed jaws provide consistent clamping, offering enhanced precision during machining. | Minimized material waste and improved product quality. |

| Enhanced Stability | Fixed systems offer superior stability compared to adjustable jaws, reducing vibrations. | Higher operational efficiency and better tool life. |

| Reduced Setup Time | Once installed, fixed jaws require less time for adjustments and setups. | Faster production cycles and increased throughput. |

| Lower Maintenance Costs | Fixed jaws typically require less maintenance than their adjustable counterparts. | Cost savings over time and greater reliability in production. |

| Versatility | Can be designed for various shapes and sizes of workpieces. | Adaptable to multiple production environments and applications. |

Fixed jaw technology has emerged as a crucial element in modern manufacturing, driving enhanced efficiency and productivity. By stabilizing workpieces during machining, this technology reduces the risk of errors and increases throughput. Case studies across various sectors have illuminated the advantages of implementing fixed jaw solutions, demonstrating significant time savings and consistent product quality. For instance, an automotive manufacturer reported a 30% reduction in cycle times after switching to fixed jaws, which allowed for faster and more reliable setups.

Tips for maximizing the benefits of fixed jaw technology include regularly maintaining and calibrating jaws to ensure they provide the perfect grip without damaging the workpieces. Additionally, integrating fixed jaws into a flexible manufacturing system can lead to even greater efficiency, as they can be adapted quickly to different machining operations. Another key point is to invest in training staff on best practices for handling and securing materials with fixed jaws to further minimize downtime and enhance safety in the workplace. This multifaceted approach enables manufacturers to harness the full potential of fixed jaw technology.

The market for fixed jaw technology in the manufacturing sector is poised for significant growth as industries seek more efficient and reliable production methods. As manufacturers increasingly embrace automation and advanced machinery, the adoption of fixed jaw technology, which enhances stability and precision in various applications, is becoming more prevalent. Current trends indicate that companies are investing heavily in this technology to improve their operational efficiency, particularly in sectors like portable crushers and crushing equipment, where market projections show steady growth over the next decade.

A comprehensive analysis reveals that the portable crushers market alone is expected to rise from USD 1.5 billion in 2025 to USD 2.6 billion by 2035, while the crushing equipment market is anticipated to reach USD 7.6 billion during the same timeframe. These trends highlight a broader shift towards incorporating more robust technology, driven by demand for higher productivity and cost-effectiveness. As fixed jaw technology evolves, its integration into manufacturing processes will likely redefine benchmarks for performance and operational excellence, ensuring that industries remain competitive in a rapidly changing landscape.

The landscape of modern manufacturing is continuously evolving, and the adoption of fixed jaw technology marks a significant shift from traditional clamping methods. Traditional clamping often relies on adjustable fixtures and manual intervention, which can lead to variability in the clamping force and alignment. In contrast, fixed jaw technology ensures a consistent and secure hold on workpieces, minimizing the risk of movement during machining. This stability translates into enhanced precision and reproducibility, making it a favored choice among manufacturers seeking to improve their production capabilities.

Moreover, the comparative analysis reveals that fixed jaw technology not only enhances efficiency but also reduces setup time. Traditional methods typically involve time-consuming adjustments and recalibrations, which can impede production flow. Fixed jaws, designed for specific applications, facilitate quick installations without the need for frequent alterations. This specialization allows manufacturers to streamline their processes, leading to higher throughput and reduced operational costs. As a result, the industry is increasingly recognizing the advantages of fixed jaw technology over conventional clamping, positioning it as a fundamental element in the future of manufacturing.