Choosing the right Mining Machinery Jaw Plates is crucial for optimizing the performance and efficiency of your operations. Jaw plates are essential components of jaw crushers, as they are directly involved in the crushing process of various materials. Selecting the appropriate jaw plates can significantly enhance production rates, reduce costs associated with wear and tear, and improve overall equipment reliability. However, with a myriad of options available in the market, it can be overwhelming to determine which jaw plates will best suit your specific needs. This guide will walk you through the critical factors to consider, including material compositions, design variations, and compatibility with existing machinery, ensuring you make an informed decision that maximizes productivity and extends the lifespan of your mining operations.

Choosing the right Mining Machinery Jaw Plates is crucial for optimizing the performance and efficiency of your operations. Jaw plates are essential components of jaw crushers, as they are directly involved in the crushing process of various materials. Selecting the appropriate jaw plates can significantly enhance production rates, reduce costs associated with wear and tear, and improve overall equipment reliability. However, with a myriad of options available in the market, it can be overwhelming to determine which jaw plates will best suit your specific needs. This guide will walk you through the critical factors to consider, including material compositions, design variations, and compatibility with existing machinery, ensuring you make an informed decision that maximizes productivity and extends the lifespan of your mining operations.

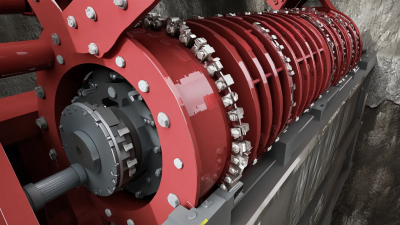

In the world of mining machinery, jaw plates play a crucial role in the efficiency and effectiveness of operations. These components, designed to crush rock and other materials, are fundamental for ensuring that mining equipment operates at its best. A well-designed jaw plate can significantly enhance performance, extending the lifespan of machinery and reducing operational costs. Understanding their importance not only aids in selecting the right plates but also in optimizing the entire mining process.

The right jaw plates can make a marked difference in the crushing process. They must be selected based on the specific characteristics of the materials being processed, including hardness and abrasiveness. High-quality materials and precise engineering ensure that jaw plates withstand the stresses of heavy-duty operations. Additionally, regular monitoring and maintenance of jaw plates can prevent costly breakdowns and improve overall productivity. Thus, investing in appropriate jaw plates is essential for any mining operation aiming for sustained success.

| Material Type | Hardness (BHN) | Applications | Lifespan (hours) | Maintenance Recommendations |

|---|---|---|---|---|

| Manganese Steel | 225-650 | Quarrying, Recycling | 750-1000 | Regular inspection, hardfacing |

| High Chrome Iron | 500-700 | Cement, Sand & Gravel | 1000-1500 | Frequent monitoring for cracks |

| Cast Steel | 200-300 | General Crushing | 500-700 | Lubrication and cleaning |

| Alloy Steel | 250-400 | Mining, Aggregates | 600-800 | Routine checks, replacement as needed |

When selecting the right jaw plates for mining machinery, it is crucial to understand the various types available and how they align with your operational needs. Jaw plates play a vital role in the crushing process; thus, their design can significantly impact the overall efficiency of the machinery. For instance, standard flat jaw plates are typically suitable for general applications, whereas corrugated or toothed variations may enhance grip and handling of more abrasive materials. Industry studies suggest that the choice of jaw plate can influence wear rates by as much as 30%, emphasizing the need for careful selection aligned with material characteristics.

Several manufacturers are now exploring innovative designs that enhance performance and longevity. For example, advancements in additively manufactured minimal surface structures are paving the way for jaw plates that not only provide superior mechanical support but also improve osseointegration during the replacement process. Such developments can be particularly important for those in harsher operational environments where durability is at a premium. The right jaw plate, tailored to specific crushing requirements and conditions, represents a key investment in maximizing productivity and minimizing downtime in mining operations.

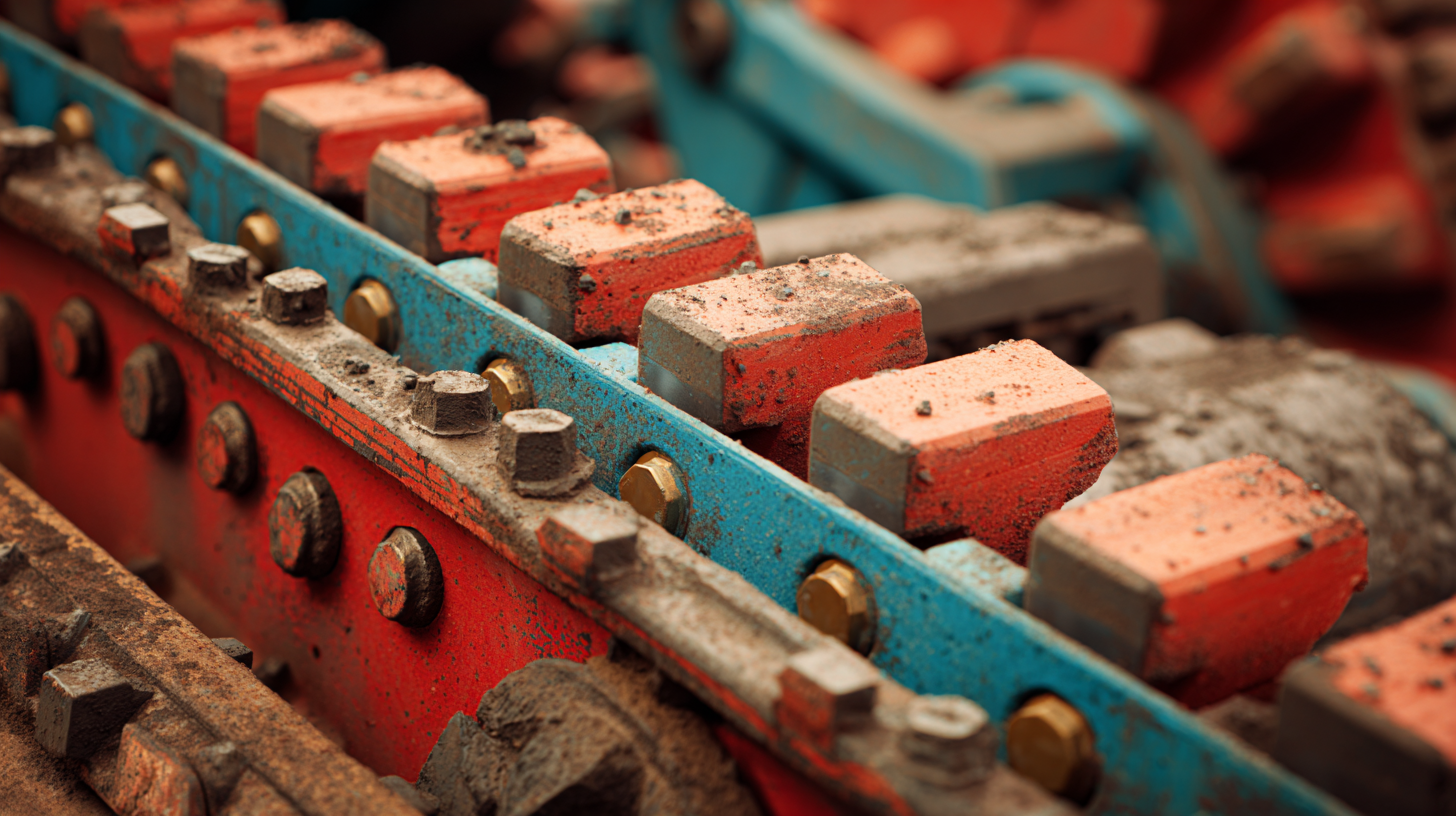

When it comes to mining operations, the choice of jaw plates plays a crucial role in determining productivity and efficiency. The material selected for these plates significantly impacts their durability and performance under demanding conditions. Common materials include manganese steel, which is lauded for its excellent wear resistance and impact strength. Manganese's ability to work-harden during operation allows jaw plates to endure the high stress of crushing rock, making it a popular choice among professionals in the industry.

Another material gaining traction is carbon steel, particularly when paired with additional coatings to enhance its resilience. Carbon steel jaw plates can provide adequate performance for less abrasive materials while being lighter than their manganese counterparts. Additionally, advanced composites and alloys are being explored to maximize efficiency while minimizing weight and costs. Understanding the specific needs of your operation and the material characteristics will ensure that you select the right jaw plates, leading to optimal performance and longevity in your mining machinery.

Maintaining jaw plates in mining machinery is crucial for ensuring optimal performance and longevity. According to a recent report by the International Journal of Mining Science and Technology, proper maintenance practices can extend the life of jaw plates by up to 30%. One essential maintenance tip is to conduct regular inspections for wear and tear. Early detection of issues such as cracks or deformation can prevent more extensive damage and costly downtime. Additionally, using the right lubrication can minimize friction, thereby enhancing the jaw plates' operational efficiency.

Another important aspect of maintenance is timely replacement. The same report indicates that jaw plates should ideally be replaced after 2,000 to 3,000 operational hours, depending on the material processed. Utilizing high-quality materials and coatings can significantly improve performance and durability. Operators should also ensure that the jaws are properly aligned during installation to avoid uneven wear, which can further compromise their lifespan. By implementing these tips, mining companies can not only maximize the efficiency of their jaw plates but also achieve substantial cost savings in the long run.

When evaluating jaw plate suppliers, there are several key factors to consider to ensure you make the right choice for your mining operations. First and foremost, assess the supplier's reputation in the industry. Look for reviews or testimonials that highlight their product quality and customer service. A reputable supplier will have a track record of reliable deliveries and support, which is crucial for minimizing downtime in your operations.

Tip: Always request samples of the jaw plates to evaluate their material quality and fit before making a large order. This will give you insights into the durability and performance of the plates, ensuring they meet your specific mining requirements.

Tip: Always request samples of the jaw plates to evaluate their material quality and fit before making a large order. This will give you insights into the durability and performance of the plates, ensuring they meet your specific mining requirements.

Another important factor is the supplier's capability to provide customized solutions. Different mining applications may require distinct jaw plate specifications, and a supplier should be able to cater to these needs. Furthermore, consider the availability of technical support and after-sales service. Having a responsive team to assist with any issues post-purchase can significantly enhance your mining operations' efficiency.

Tip: Engage with suppliers who offer a comprehensive warranty on their products. This not only reflects their confidence in their offerings but also provides peace of mind against premature wear and tear.