The importance of the Jaw Crusher Plate in the crushing industry cannot be overstated. As the primary component, it significantly impacts the efficiency of the crushing process. According to a report by the Mining Equipment Research Institute, a high-quality Jaw Crusher Plate can enhance crushing effectiveness by up to 30%. This highlights its crucial role in optimizing production cycles.

Industry expert Dr. Emily Carter states, “The Jaw Crusher Plate not only affects the reduction ratio but also influences wear resistance.” Her insights emphasize the potential performance challenges when using substandard plates. For instance, a poorly designed plate may lead to increased downtime and maintenance costs, which can adversely affect productivity.

Moreover, different materials used in manufacturing Jaw Crusher Plates can yield varying results. While manganese steel is widely preferred for its durability, some operations may benefit from ceramic composite options. Consideration of these factors is essential, as improper selection can lead to inefficiencies. This area demands careful reflection and attention to ensure optimal operation in crushing applications.

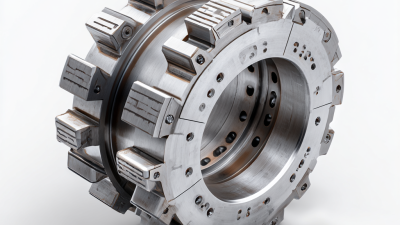

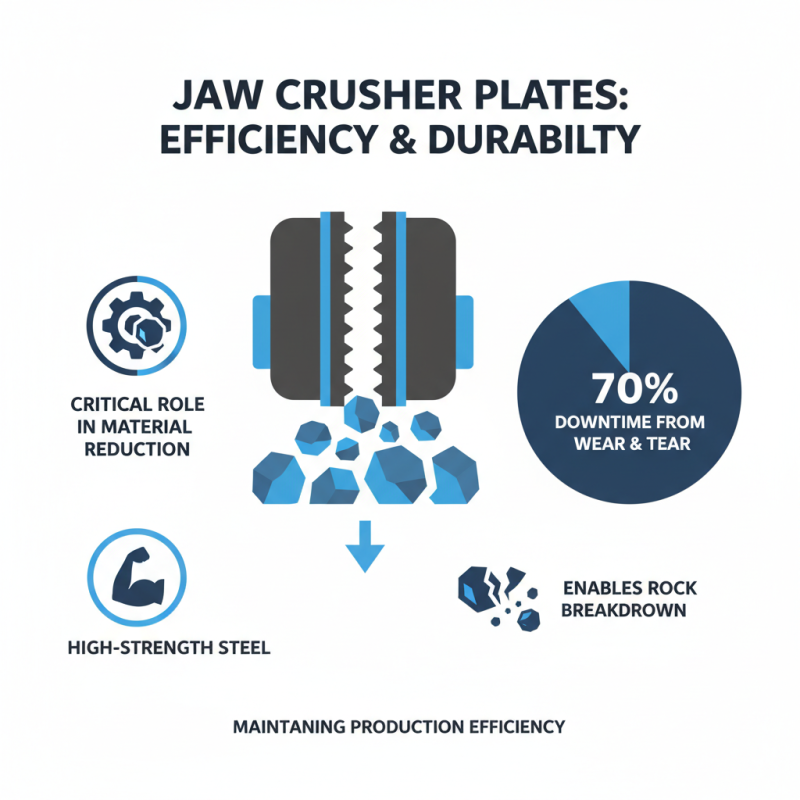

Jaw crusher plates play a critical role in material reduction efficiency. These plates, usually made from high-strength steel, are fundamental for crushing a variety of materials. They create the necessary crushing force, enabling the jaw crusher to break down large rocks into manageable sizes. According to industry reports, approximately 70% of operational downtime in crushers results from wear and tear of these plates. This underlines their importance in maintaining production efficiency.

Efficient crushing relies heavily on the design and material of the jaw plates. A recent study indicated that using optimized material composition can enhance the lifespan of these plates by up to 25%. This increase can lead to substantial cost savings over time. Higher durability reduces the frequency of replacements, which can disrupt production schedules. However, not all operations give plate wear the attention it deserves. Many overlook the impacts of irregular maintenance schedules on performance.

Moreover, the effectiveness of the crushing process is tied to the correct installation of jaw plates. Incorrect alignment can lead to uneven wear, ultimately reducing efficiency. In reality, many operators may fail to monitor these subtle changes, which can result in significant losses. Understanding the dynamics of jaw plates is vital for achieving optimal material reduction. Efficient crushing isn't just about having robust equipment; it's also about recognizing the crucial role of each component involved.

Jaw plates play a crucial role in the crushing process of a jaw crusher. They serve as the primary interface where raw materials are broken down into manageable sizes. High-quality jaw plates ensure optimal interaction with the material, which enhances crushing efficiency. Industry reports indicate that the right jaw plates can increase production by 20-30%. This is significant in high-demand environments.

The design and material of jaw plates also affect wear resistance and lifespan. For instance, manganese steel is known for its durability and ability to absorb shock. However, not all jaw plates perform equally. Some may wear out rapidly, leading to increased costs and downtime. Studies show that regular monitoring of wear patterns can extend the life of these plates. This proactive approach is essential for maintaining efficiency in operations.

In many cases, operators overlook the importance of maintaining jaw plates. A lack of attention can lead to undersized output and reduced productivity. Misalignments or worn areas can affect the crushing dynamics. Adopting a systematic maintenance routine can remedy these issues. Data reveals that companies focused on regular inspections improve output consistency by approximately 15%. Investing in quality jaw plates and maintenance is crucial for achieving efficient crushing.

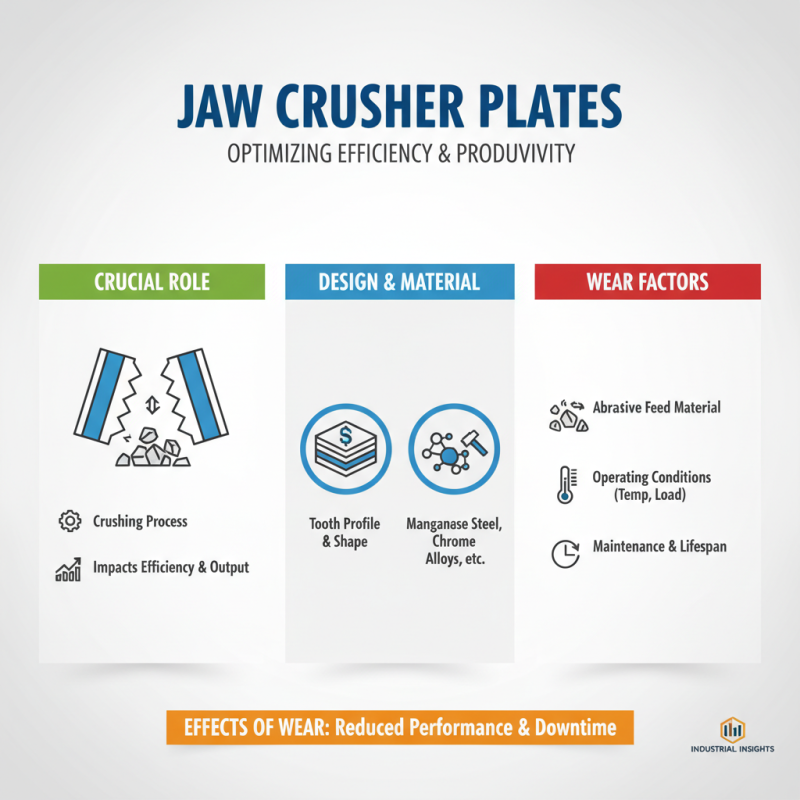

Jaw crusher plates play a crucial role in the crushing process. Their design and material choice directly impact efficiency and productivity. However, several factors influence their wear rates, which can significantly affect performance over time.

Material quality is essential. Harder materials often lead to slower wear rates but can also cause increased stress on the entire machine. The feed type matters too—larger, more abrasive rocks wear out plates faster than smaller, softer materials. Sometimes, the feeding method can be improvised for efficiency, yet this can lead to uneven wear on the plates.

**Tips:** Regular inspections are vital. Check for cracks or unusual wear patterns. Adjusting the jaw settings can help optimize efficiency and prolong plate life. Additionally, consider adjusting your maintenance schedule based on wear patterns. Keep an eye on environmental factors too, like humidity or dust, as they can contribute to wear.

The jaw plate is crucial in the crushing process. It directly affects efficiency and product quality. Selecting the right material is essential for durability. High manganese steel is commonly used. It can withstand heavy wear and stress. However, not all materials perform equally well in various conditions.

When designing jaw plates, industry standards play a vital role. Thickness and shape impact how effectively rocks are crushed. The profiles should allow for optimal crushing and minimal downtime. Some designs may lead to inefficiencies, causing more damage than benefit. For instance, overly complex shapes can complicate production and maintenance.

Manufacturers must constantly review their designs. What worked in the past might not suit today’s needs. Regular testing and feedback cycles can improve outcomes. However, some companies neglect this aspect, risking costly failures. It’s a challenge to balance cost with efficiency and longevity. Choosing the right jaw plate is a strategic decision that heavily influences overall productivity.

When it comes to crushing performance, proper jaw plate adjustment plays a critical role. Jaw plates must be set correctly to achieve maximum efficiency. If the plates are too close together, the material may not be crushed effectively. If they are too far apart, the material may pass through without proper comminution. This setup can directly affect throughput and product quality.

Regularly monitoring the jaw plate's condition is crucial. Worn-out plates can lead to poor performance and increased wear on other components. It's vital to make adjustments based on wear patterns and material characteristics. Ignoring these adjustments can create inefficiencies, leading to increased costs.

Tips for optimal adjustment include checking the spacing regularly. Make small adjustments to avoid dramatic changes. Understand the material being crushed; different materials might require different setups. Always keep an eye on vibration; excessive movement can indicate misalignment. If results are not meeting expectations, it's time for a reevaluation of your setup. Attention to detail in plate adjustment can lead to significant improvements in overall performance.