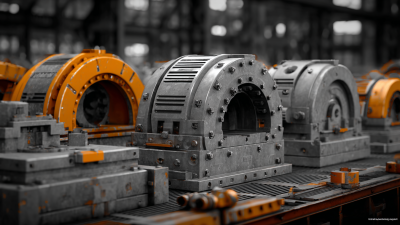

In the aggregate and mining industries, the efficiency of equipment directly impacts productivity and profitability. The "Stone Crusher Fixed Jaw" is a critical component that significantly influences the performance of a stone crusher. According to a report by Technavio, the global stone crushing equipment market is expected to grow by USD 2.29 billion between 2022 and 2026, highlighting the increasing demand for optimized machinery. Proper maintenance and optimization of the fixed jaw can enhance crushing efficiency, reduce downtime, and lower operational costs. Industry experts emphasize that adhering to best practices and understanding key factors such as material properties, wear patterns, and the crushing process itself are essential in maximizing the fixed jaw’s potential. By focusing on these elements, operators can ensure their equipment not only meets but exceeds performance expectations in a competitive market.

The fixed jaw of a stone crusher plays a crucial role in determining overall performance and efficiency. As a primary component, it serves as a stationary surface against which the material is crushed. According to industry reports, improper alignment or wear on the fixed jaw can lead to a decrease in throughput by as much as 20%. This makes it imperative for operators to regularly inspect and maintain this component to ensure optimal functioning.

In addition to regular maintenance, selecting the appropriate material for the fixed jaw can significantly enhance performance. Studies show that high manganese steel, often used for fixed jaws, offers better wear resistance and can increase the lifespan of the component by up to 50% compared to standard steel. Understanding the wear patterns and adjusting the working parameters of the crusher, such as the closure setting and speed, can lead to improved crushing efficiency and reduced operational costs.

Proper attention to the fixed jaw not only boosts productivity but also extends the service life of the entire crushing system.

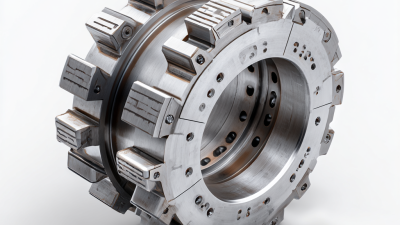

The efficiency and longevity of a stone crusher's fixed jaw are influenced by several key factors. First, the quality of the materials used in the fixed jaw's construction plays a substantial role. According to a report by the International Journal of Rock Mechanics and Mining Sciences, high-quality manganese steel is preferred due to its exceptional wear resistance and toughness, leading to extended service life. In fact, substituting lower-quality materials can reduce the lifespan of the fixed jaw by up to 30%, resulting in increased costs for replacements and downtime.

In addition to material quality, the design and geometry of the fixed jaw are critical for optimizing performance. Studies indicate that a well-angled design can enhance the crushing efficiency by optimizing the material flow, thereby reducing the likelihood of jams. A report from the Mining Equipment Association suggests that an optimized fixed jaw design can increase throughput by approximately 15%. Regular maintenance and periodic inspections are also essential to ensure that wear patterns are addressed early, preventing unexpected failures and ensuring that the crushing operation remains productive and efficient.

Regular maintenance of fixed jaws is crucial for optimizing the performance of stone crushers. The first key practice involves routine inspections to identify wear and tear. This includes checking for cracks, misalignment, and excessive wear on the jaw surfaces. By addressing these issues early, operators can prevent costly downtime and maintain optimal crushing efficiency.

Another essential aspect of maintenance is proper lubrication of the jaw components. Ensuring that all moving parts are adequately lubricated minimizes friction and wear, leading to extended lifespan and enhanced performance. Operators should follow manufacturer guidelines for lubrication intervals and use the correct lubricant to preserve the integrity of the components.

Additionally, regular cleaning of the fixed jaw area is vital. Accumulated debris can obstruct optimal function and reduce efficiency. Implementing a consistent cleaning schedule allows for better visibility of potential issues and maintains a safe working environment. In summary, focusing on inspection, lubrication, and cleanliness can significantly enhance the performance of your stone crusher fixed jaw.

The durability and performance of the fixed jaw in a stone crusher are significantly influenced by materials selection. High-quality materials not only enhance the lifespan of the fixed jaw but also improve its operational efficiency. For instance, using advanced materials such as high-tensile steels can lead to a more robust structure that withstands higher stresses during crushing operations. Additionally, incorporating wear-resistant alloys can minimize wear and tear, ensuring that the fixed jaw maintains its shape and effectiveness over time.

**Tips:** When selecting materials for the fixed jaw, consider factors such as tensile strength, ductility, and resistance to wear. It's also crucial to evaluate the operational environment and the types of materials being crushed. Regular maintenance and monitoring can help identify any wear patterns early, allowing for timely replacements and modifications.

Another critical aspect is the design of the fixed jaw itself. An optimum design that accounts for various loading scenarios can significantly influence performance. Studies have shown that a well-designed jaw plate can improve the crushing process by ensuring effective material flow and reducing blockages, which ultimately minimizes downtime for maintenance. Proper coupling of design and material selection creates a more efficient and durable fixed jaw system.

| Material Type | Hardness (Mohs Scale) | Tensile Strength (MPa) | Wear Resistance | Typical Applications |

|---|---|---|---|---|

| Steel | 4-8 | 370-600 | Good | General Crushing Applications |

| High Manganese Steel | 5-6 | 700-900 | Excellent | Ore and Hard Rock Crushing |

| Alloy Steel | 4-7 | 500-800 | Very Good | Construction Materials |

| Ceramic Composite | 8-9 | 300-500 | Outstanding | High Abrasion Situations |

Upgrading and modifying the fixed jaw of a stone crusher is crucial for enhancing its performance and efficiency. One effective approach is to analyze the existing jaw design and identify areas for improvement. This could include altering the tooth profile or changing the fixed jaw's angle to maximize the crushing force applied to the stones. By selecting the right materials that provide higher wear resistance, operators can significantly extend the lifespan of the fixed jaw, reducing downtime and maintenance costs.

Moreover, the integration of advanced technologies as part of these modifications can lead to better performance. For instance, incorporating wear sensors helps in monitoring the condition of the fixed jaw in real-time, allowing for timely interventions when wear levels reach critical points. Additionally, upgrading to microstructural composites can enhance the strength and durability of the jaw, enabling it to withstand the high-stress environment typical in stone crushing operations. Overall, focusing on these strategic upgrades ensures optimal functionality and maintains high output levels in stone crushing processes.