Cone Crusher Parts play a crucial role in the efficiency and longevity of cone crushers. Understanding these components can significantly impact the performance of your machinery. Each part serves a specific function that, when optimized, increases productivity.

When it comes to cone crushers, not all parts are created equal. Some parts may wear out quicker than others. Regular maintenance is essential for longevity. For example, the mantle and concave must fit perfectly to ensure correct crushing. If these parts are worn or damaged, they will lead to inefficiency.

The top ten components discussed here will help you grasp their importance. Knowing which Cone Crusher Parts to prioritize can save time and money. Investing in high-quality parts is critical. However, it is easy to overlook small details. Regular checks can prevent costly repairs.

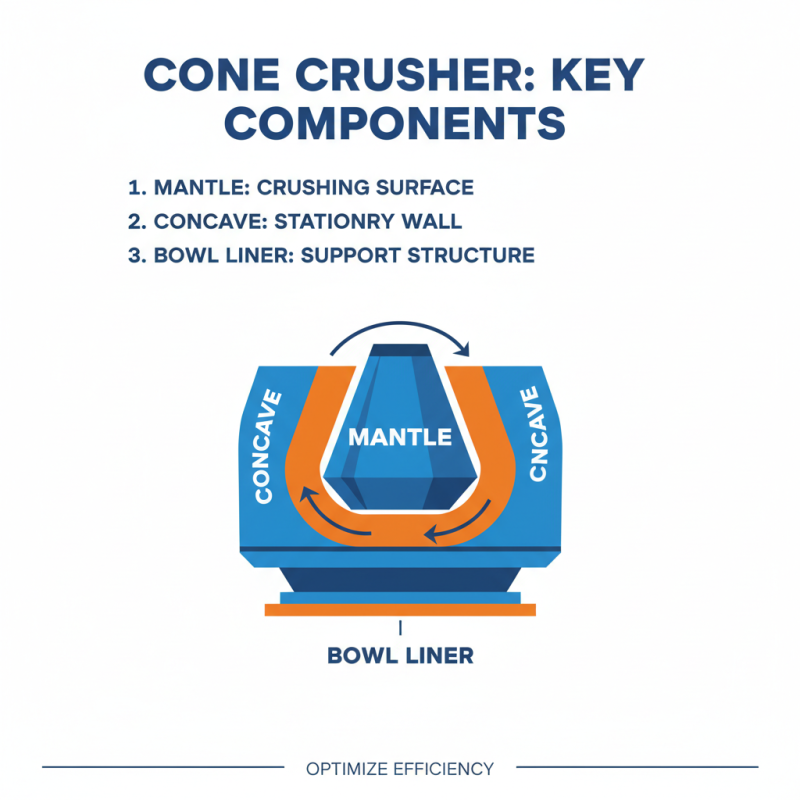

Understanding the anatomy of a cone crusher is crucial for effective operation. The core components include the mantle, concave, and the mainframe. The mantle rotates and crushes the materials. It is essential for maintaining appropriate wear. Concaves sit stationary, acting as a crushing surface. The interaction between these two parts determines efficiency.

Another significant part is the eccentric shaft. It is responsible for the mantle's movement. Without proper lubrication, the shaft can wear out quickly. Regular checks on the eccentric and its bearings ensure smooth operation. Then, there are the hydraulic cylinders. They adjust the gap between the mantle and concave, allowing varied sizes of materials. Misalignment can cause excessive wear on components.

Lastly, the drive assembly powers the entire process. It's fascinating yet complex. A failure in this system can halt production entirely. Even minor issues can lead to major setbacks. Maintaining these components requires attention. Operators need to be proactive in inspections, as overlooking small details can result in costly repairs.

Cone crushers are vital in mining and construction. These machines rely on several key components to function effectively. Understanding these parts can help operators enhance efficiency. The most important components include the mantle, concave, and bowl liner. The mantle is essential for crushing action, while the concave acts as the stationary surface. The bowl liner supports both the mantle and the concave.

One study reveals that proper maintenance of these components can increase productivity by up to 30%. However, wear and tear are inevitable. Operators often overlook the importance of regular inspections. Skipping maintenance can lead to expensive repairs and downtime. In fact, it can cost companies up to $1 million each year due to equipment failure.

Other crucial parts include the shaft, bearings, and hydraulic system. The shaft transfers force, while bearings ensure smooth operation. Hydraulic systems provide pressure for efficient crushing. Data shows that inadequate lubrication can significantly reduce lifespan. This highlights the need for a reliable maintenance schedule. Operators must be proactive in addressing wear to maintain optimal performance and safety.

Cone crushers are crucial in mining and aggregate industries. They provide size reduction for various materials. Understanding wear parts is key to maximizing performance and lifespan. Essential wear parts include liners, mantle, and bowl. These components directly impact the efficiency of the crushing process.

Studies show that worn liners can reduce throughput by up to 20%. If the wear parts are not replaced promptly, the crusher may face operational issues. Regular maintenance can improve equipment lifespan, reducing costs. A lack of attention to wear parts often leads to unexpected breakdowns.

Proper material selection for wear parts is vital. High-quality steel alloys can withstand extreme conditions, enhancing performance. According to industry reports, well-maintained wear parts can improve productivity significantly. Ignoring their importance can lead to lower output and increased operational costs. Exploring these details can ensure your equipment runs smoothly.

| Part Name | Material | Function | Importance in Performance |

|---|---|---|---|

| Mantle | High Carbon Steel | Crushes material against cone | Critical for sizing material |

| Concave | Manganese Steel | Forms the outer surface for crushing | Enhances crushing efficiency |

| Eccentric Shaft | Alloy Steel | Drives the mantle rotation | Vital for effective crushing |

| Crusher Bowl | High Tensile Steel | Supports the concave assembly | Ensures stability during operation |

| Hydraulic Cylinder | Steel | Adjusts the gap area | Crucial for product size control |

| Jaw Plate | Manganese Steel | Engages with the mantle | Directly affects the crushing action |

| Feed Hopper | Steel | Stores and feeds material | Essential for consistent flow |

| Dust Seal | Rubber | Prevents dust from entering | Maintains internal cleanliness |

| Main Frame | Steel | Provides structural support | Critical for overall stability |

| Drive Belts | Polymer | Transmits power from the motor | Vital for operational efficiency |

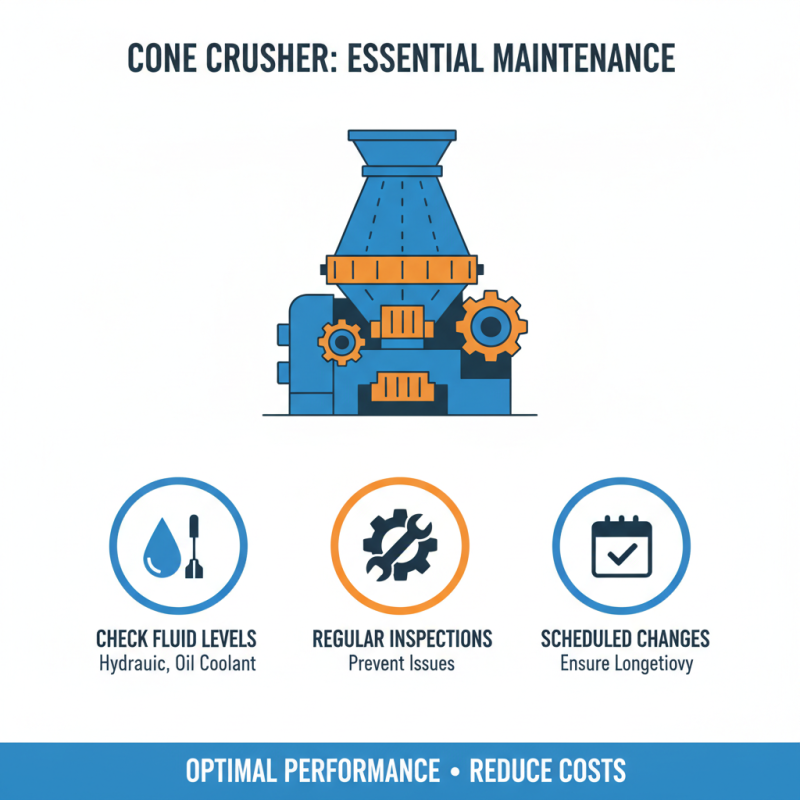

Maintaining a cone crusher is essential for ensuring its longevity and optimal performance. Regular maintenance can prevent unforeseen issues and costly repairs. Start by checking fluid levels. Hydraulic fluid, lubrication oil, and coolant are critical for smooth operation. Develop a routine to inspect and change these fluids as needed.

Another important tip is to keep the crusher clean. Dust and debris can accumulate, affecting performance. After each work shift, promptly remove any foreign materials. Inspect the wear parts regularly. They can dictate the efficiency of your machine. Replacing worn parts on time can save you from bigger headaches later on.

Pay attention to vibration levels during operation. Excessive vibrations may indicate internal issues. Listening to unusual sounds is also crucial. If you notice anything off, stop the machine to investigate. Keeping detailed logs of maintenance activities can help in identifying patterns and potential problems. This proactive approach will enhance the lifespan of your cone crusher.

When considering cone crushers, the choice between aftermarket and OEM parts can significantly influence both performance and cost. Aftermarket parts often present a more budget-friendly option. They can also deliver competitive quality. However, OEM parts usually ensure a perfect fit and adherence to manufacturer standards. According to industry reports, nearly 30% of operators who used aftermarket parts experienced premature wear.

On the flip side, OEM parts generally come with a warranty, providing peace of mind. They might have a premium price, but this investment can lead to fewer breakdowns. A study showed that using OEM components reduces operational downtime by approximately 20% compared to aftermarket alternatives. This is crucial for maintaining productivity in mining operations.

Tip: Always assess the total cost of ownership when choosing parts. Initial savings may not always equate to long-term benefits. Remember that performance and reliability should be priorities. Additionally, researching performance reviews on aftermarket parts can help. Not all aftermarket options are created equal, so meticulous evaluation is necessary.