In the realm of aggregate production, cone crushers are pivotal in achieving superior material size reduction and shaping. However, the performance of these machines largely depends on the quality and condition of their components. John Smith, an industry expert with over 20 years of experience in aggregate machinery, once stated, "Understanding the intricacies of cone crusher parts is essential for maximizing uptime and minimizing operational costs." This insight highlights the importance of selecting the right Cone Crusher Parts to ensure both efficiency and longevity of the equipment.

As the demand for high-quality crushed materials continues to rise, the significance of optimal performance in cone crushers cannot be overstated. Each component, from the mantle to the wear plates, plays a critical role in the effective functioning of the machine. Neglecting any aspect of these Cone Crusher Parts can lead to diminished performance, increased downtime, and ultimately, financial losses. Thus, it is crucial for operators and maintenance personnel to be well-informed about the top components necessary for maintaining peak performance in their cone crushers. In this article, we will delve into the seven essential Cone Crusher Parts that every operator should prioritize to enhance operational efficiency and ensure sustained productivity.

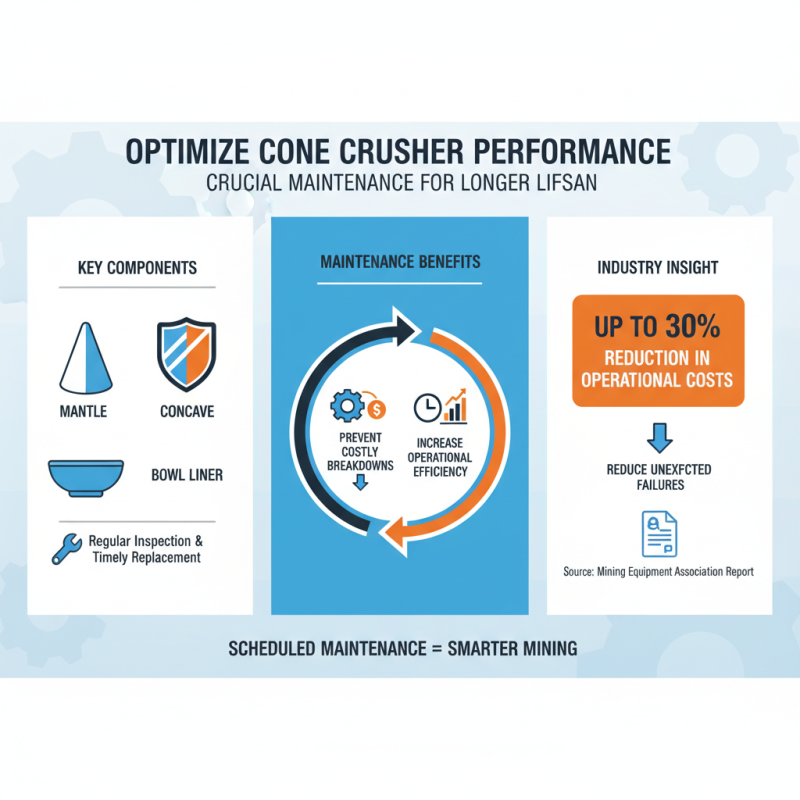

A cone crusher is a crucial component in various industries, especially in mining and construction. To ensure efficient operations, understanding the key components of a cone crusher is essential. The mantle and bowl liner are two critical parts, as they form the primary crushing surfaces. The mantle moves, crushing the material against the stationary bowl liner, which shapes the crushed product. Regular inspection and timely replacement of these parts can significantly enhance the crusher's productivity.

Another vital component is the hydraulic system, which regulates the crushing force. It provides the ability to adjust the opening of the crusher, allowing operators to control the size of the output material effectively. Maintaining the hydraulic fluid at optimal levels ensures that the system operates smoothly, preventing potential breakdowns.

Tips: To maximize performance, operators should routinely check for wear on the liners and the hydraulic components. Implementing a maintenance schedule will not only prolong the life of these essential parts but also improve the overall efficiency of the cone crusher. Additionally, ensuring proper lubrication of moving parts can reduce friction and wear, further enhancing operational performance.

Understanding the functionality of different cone crusher parts is essential for maximizing performance and prolonging the lifespan of the equipment. Each component in a cone crusher plays a critical role in the crushing process, contributing to the efficiency and output of the machine. Key parts include the mantle, bowl liner, and cone head, which work together to crush and screen materials. The mantle is responsible for crushing the material against the bowl liner, while the cone head supports the mantle and ensures proper alignment and stability during operations.

When maintaining and operating a cone crusher, regular inspection of these parts is crucial. Tips for ensuring optimal performance include checking for wear and tear, ensuring proper lubrication, and replacing worn parts promptly. It is also essential to keep the crusher's discharge setting at the correct level to avoid unnecessary strain on the components. Another useful tip is to monitor the feed size and consistency, as this greatly impacts the efficiency and effectiveness of the cone crusher.

Understanding the individual roles of these parts can help operators make informed decisions regarding maintenance and replacement, thus enhancing overall productivity. Optimizing the functionality of the cone crusher leads to better throughput and reduced downtime, ultimately contributing to the efficiency of operations.

Proper maintenance of cone crusher parts is crucial for ensuring optimal performance and extending the lifespan of this essential equipment. Regular inspection and timely replacement of critical components such as the mantle, concave, and bowl liner can prevent costly breakdowns. According to a recent industry report by the Mining Equipment Association, scheduled maintenance can reduce operational costs by up to 30%, as it minimizes the risk of unexpected failures and increases the overall efficiency of the crushing process.

To maintain the longevity of cone crusher parts, it is vital to monitor the wear and tear of essential components. Implementing a routine check for wear patterns and adjusting the settings accordingly can help in significantly prolonging the life of the part. Furthermore, utilizing proper lubrication practices, as highlighted in a study from the International Journal of Mining Science, can enhance the performance of the crusher and decrease the likelihood of overheating, which is a common issue that leads to premature part failure. Regular cleaning and inspection of the hydraulic systems also play a key role in preventing contamination, thereby ensuring smoother operation and safeguarding expensive components.

The performance of a cone crusher is heavily influenced by the quality of its parts. Each component, from the liners to the bearings, plays a crucial role in maintaining the efficiency and longevity of the machine.

High-quality parts ensure that the crusher can handle the stresses of continuous operation without premature wear or failure. This not only maximizes productivity but also minimizes downtime for repairs and replacements, which can be costly for operators.

Moreover, the compatibility of parts significantly impacts overall performance. When all parts are designed to work cohesively, they facilitate smoother operation, better material flow, and more consistent product size.

Key Benefits: This synergy leads to enhanced crushing efficiency, resulting in higher throughput and reduced energy consumption. Investing in superior components is thus essential for achieving optimal performance from a cone crusher, ensuring that it meets the demands of heavy workloads and provides reliable output over time.

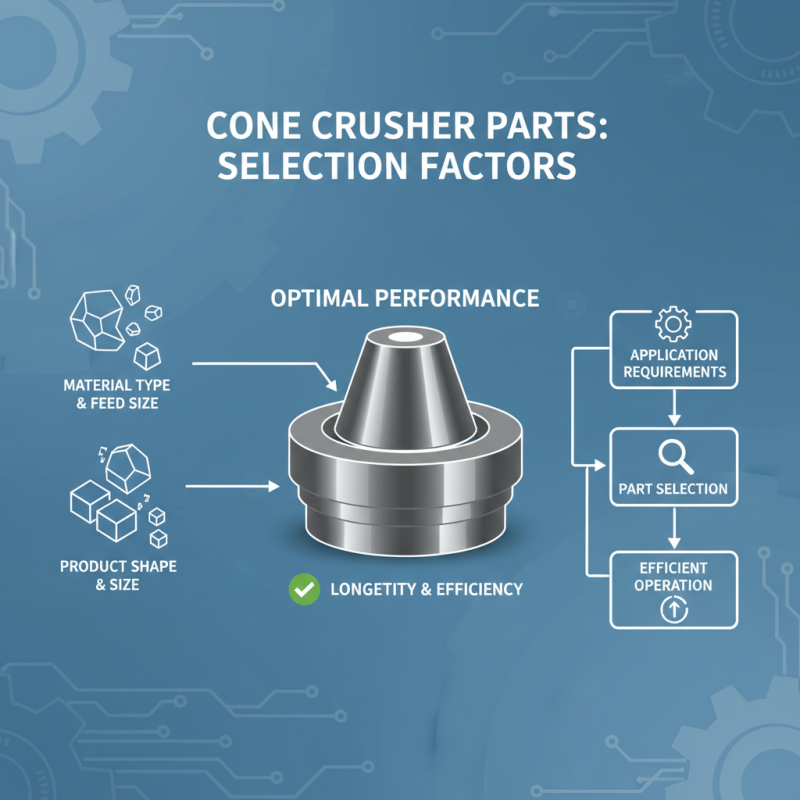

When selecting the right cone crusher parts for your application, it’s essential to consider several factors that can greatly impact performance and longevity. The first step is to understand the specific requirements of your operation, including the type of material being processed, the size of the feed, and the desired product shape and size. Matching the correct cone crusher parts to these conditions will ensure that your equipment runs efficiently and effectively.

Tips for optimal performance include regularly inspecting wear parts such as liners and bushings. Keeping an eye on the wear levels can help you avoid unplanned downtime and maintain production levels. Additionally, selecting parts made from high-quality materials can enhance durability and reduce the frequency of replacements, ultimately saving time and costs in the long run.

Another important aspect to consider is the compatibility of parts with your existing equipment. Using components that are specifically designed for your crusher model not only ensures better fit and functionality but also maximizes the machine's operational efficiency. A thorough understanding of your system can guide you in making informed decisions about part selection and maintenance strategies, contributing to a smoother operation overall.