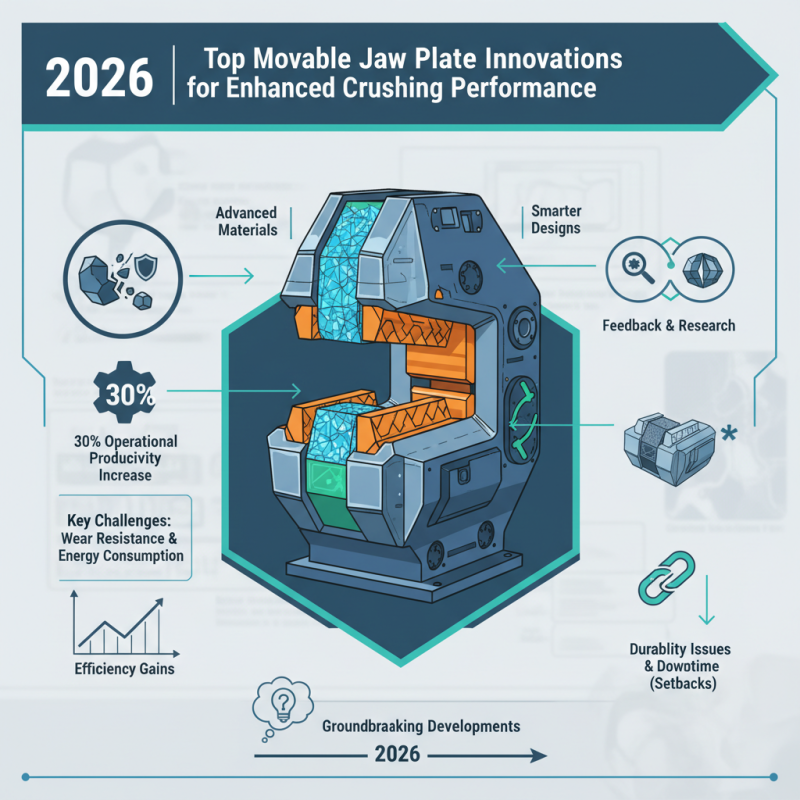

The innovations surrounding movable jaw plates are crucial for enhancing crushing performance in mining and construction. In recent years, industry reports have shown that efficiency gains in crushers have increased operational productivity by up to 30%. Experts predict that advancements in materials and design will further push these boundaries. "The future of movable jaw plate technology lies in smarter designs that cater to heavier workloads," says Dr. John Smith, a leading expert in crushing technologies.

As the demand for mineral resources grows, the need for efficient crushing solutions becomes more pressing. Movable jaw plates are at the heart of this process. They play a vital role in determining the crusher's effectiveness. Innovations are expected to address key challenges, such as wear resistance and energy consumption, both of which remain significant concerns in the industry.

Nevertheless, not all advancements meet expectations. Some new designs have faced issues with durability, leading to unintended downtime. Continuous feedback and research are essential for refining these innovations. The journey toward optimal movable jaw plates involves not only embracing new technology but also learning from setbacks and improving existing systems. As we look forward to 2026, the potential for groundbreaking developments remains vast, yet challenging.

Innovations in movable jaw plate design are transforming the crushing industry. The new materials used in manufacturing provide better durability and resistance. Engineers experiment with lightweight composites, enhancing efficiency while maintaining strength. This shift allows crushers to operate more effectively under heavy loads.

Some designs incorporate advanced geometries to improve material flow. These shapes can minimize bottlenecks during operation. However, flawed designs still exist, leading to inefficient crushing. Inadequate testing can result in unexpected failures. Continuous improvement is essential for these innovations to meet industry demands.

Collaboration between engineers and material scientists has sparked creative solutions. Customizable jaw plates are emerging, adapting to various materials and conditions. Yet, achieving the perfect balance between efficiency and durability remains a challenge. Users must consider the trade-offs when selecting new designs.

The materials used in movable jaw plates are seeing significant advancements in 2026. This year, the focus is on high-strength alloys and wear-resistant composites. These innovations are changing how crushing equipment performs. According to a recent industry report, using advanced materials can increase the lifespan of jaw plates by up to 30%. This reduction in wear translates to fewer replacements and lower operational costs.

Another noteworthy development is the shift towards lighter materials without sacrificing strength. Engineers are experimenting with titanium and advanced ceramics. These materials reduce the overall weight of the jaw plate. A lighter design improves efficiency, allowing for more agile operations. Yet, there are challenges in the manufacturing process. Achieving the perfect balance between weight and durability remains a key issue.

Moreover, the environmental impact of new materials cannot be overlooked. Some manufacturers are considering recycled materials for sustainable production. This approach could minimize the carbon footprint of production. However, the long-term durability of these recycled options is still under scrutiny. Testing needs to be more thorough to ensure they meet industry standards. Not every innovation leads to immediate success, and reflection is essential for progress.

The crushing industry is evolving rapidly. Advanced technologies are redefining how movable jaw plates are designed. Enhanced materials and innovative geometries are making jaw plates more efficient. These changes lead to greater crushing performance and reduced downtime. The focus is on maximizing output and minimizing maintenance needs.

However, it's essential to recognize the challenges. Not all advancements yield immediate results. Some innovations may require a learning curve to optimize. Operators might struggle to adapt to new systems. There can be a disconnect between technology and practical use in the field. Feedback from the ground is crucial for continuous improvement.

In an ever-competitive market, staying ahead means embracing these innovations. Yet, there's a fine line between adopting new technologies and over-engineering. It's vital to question if every new feature truly enhances efficiency. Understanding the impact of advanced technology on crushing will guide future developments, ensuring they meet real-world demands.

The evolution of jaw plates in crushing applications shows significant innovations. Traditional jaw plates often struggle with wear and tear. They may not provide optimal performance over time. Innovations focus on materials that resist wear better. Some newer designs offer a unique surface profile. This can enhance the crushing process and increase efficiency.

In a comparative analysis, traditional jaw plates typically use standard steel. This material is effective, yet often leads to frequent replacements. Innovative designs incorporate advanced alloys or composites. These materials tend to last longer and maintain their shape under extreme pressure. However, manufacturers still face challenges. Not all innovative designs perform well in every application. Continuous testing and feedback loops are crucial for improving these products.

Adoption of innovative jaw plates requires thorough examination. Some users may find the transition difficult. Not every machine can accommodate new designs without modifications. Additionally, cost considerations play a role in the decision-making process. Striking a balance between cost and performance is essential for buyers.

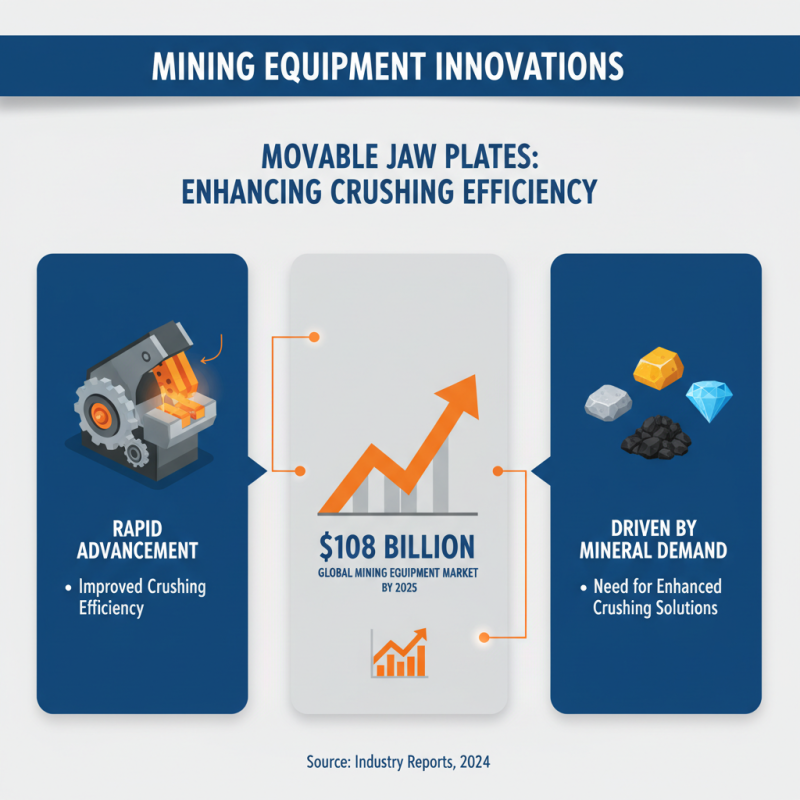

The mining industry is experiencing rapid advancements in the development of movable jaw plates. These innovations are critical for improving crushing efficiency. Recent reports indicate that the global market for mining equipment is expected to reach $108 billion by 2025. Rising demands for minerals drive the need for enhanced crushing solutions.

Innovative materials and designs play a significant role in the performance of movable jaw plates. For instance, incorporating advanced alloys can reduce wear and tear. Industry studies show that wear resistance can improve by up to 30% with these new materials. However, some manufacturers still rely on outdated designs which may not meet emerging standards.

Sustainability is another focal point in future developments. The push for eco-friendly materials reflects broader industry trends. Some companies report they aim for a 15% reduction in carbon footprint by using recycled materials in their products. Nonetheless, challenges remain in balancing cost and sustainability. Innovative concepts spark excitement, yet practical implementation requires thorough assessment.