The Moving Jaw is a crucial component in various mechanisms, particularly in robotics and machinery. Expert Dr. Emily Carson, a leading figure in mechanical engineering, emphasizes this by stating, "Understanding the Moving Jaw's dynamics is vital for innovation." This highlights the importance of grasping how the Moving Jaw operates in different applications.

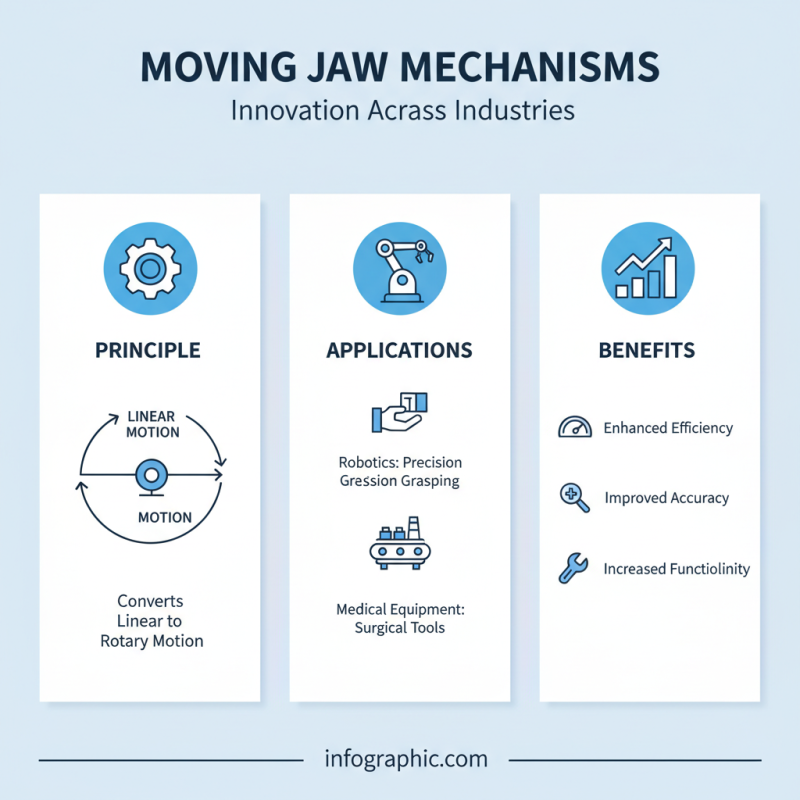

Typically, the Moving Jaw's function is to convert linear motion into rotational motion. This transformation is essential in devices ranging from simple machines to complex robotics. For instance, in a robotic arm, the Moving Jaw allows precise control over gripping objects. However, many overlook its role in overall performance.

Exploring the workings of the Moving Jaw prompts questions about design and efficiency. Engineers often encounter challenges that require creative solutions. The intricacy of this component leads to both innovation and difficulties in understanding its full potential. Recognizing these hurdles can foster deeper insights into mechanical functionality.

The moving jaw plays a pivotal role in mechanical systems. It acts as the primary driver in various applications. When we think of machinery, we often overlook this component. Yet, its functionality is fundamental. The moving jaw creates motion by converting mechanical energy. This is essential for devices like compressors and crushers.

Understanding the mechanics of the moving jaw requires a close examination. It operates through a series of levers and pivots. The design varies greatly across different machines. Some jaws move in a straight line, while others have an arc-like motion. This complexity can lead to inefficiencies if not designed properly.

Machine operators must be aware of wear and tear. Regular maintenance is crucial to ensure optimal performance. An overlooked moving jaw can lead to significant issues. Misalignment or excessive wear can halt production. Small changes in angle or position can result in drastic variations in performance. Engaging with this component requires continual learning and adaptation.

Understanding the design principles behind the moving jaw mechanism requires a grasp of its internal components and their functions. The moving jaw operates primarily to convert linear motion into rotational movement. This mechanical feature is crucial in various applications, ranging from industrial machines to robotics. According to a recent industry report, about 60% of mechanical failures stem from inadequate designs of such mechanisms.

When designing a moving jaw, it’s vital to consider stress distribution. Poorly designed jaws can lead to uneven wear or failure under load. The materials used should withstand robust conditions. Engineers often simulate these forces using software tools to predict performance. However, simulations may not always reflect real-world conditions. This discrepancy can result in unforeseen issues in operational settings.

Tips: Always prototype before finalizing designs. This helps identify potential flaws. Regular testing can also reveal weaknesses in the mechanism. An overlooked aspect in design principles is the ease of maintenance. Make sure to account for accessibility in your designs. This ensures that systems remain functional over time without excessive downtime.

The moving jaw is crucial in various engineering mechanisms. It plays a significant role in devices like jaw crushers and clamping devices. These mechanisms utilize a moving jaw to crush, grip, or move materials effectively. Jaw crushers can achieve a reduction ratio of up to 6:1, making them efficient for crushing tasks.

Different types of mechanisms utilize moving jaws. For example, in a hydraulic press, the moving jaw applies pressure to materials. This process leads to effective molding. In robotic arms, the moving jaw enables precise gripping of objects. Such designs help in automation across industries. According to a recent industry report, the mechanized gripping market is projected to grow by 8% annually.

Tips: Ensure that the moving jaw design considers material fatigue. Regular testing can prevent failures. Maintenance is essential for optimal performance. Pay attention to wear patterns that may indicate design flaws. These insights contribute to reliability and efficiency in engineering applications.

This chart illustrates the distribution of various types of mechanisms utilizing moving jaws in engineering applications, showcasing the percentage of their usage across different industries.

The moving jaw plays a crucial role in various mechanical systems. Its motion greatly influences the overall efficiency of these mechanisms. Understanding how it operates helps engineers optimize designs. The dynamics of the moving jaw can be complex. It involves factors such as speed, force, and material properties.

When analyzing the motion, consider how the jaw pivots. This pivoting action affects the force distribution throughout the mechanism. It’s important to account for the weight of the moving jaw. Heavier jaws demand more energy to move. Proper balance is key; an unbalanced system can lead to excessive wear or failure.

The dynamics should also include friction analysis. Friction can slow down motion and lead to heat generation. Heat could alter the material properties over time, that’s a concern. Moreover, understanding the limits of motion is vital. If a jaw moves too far, it can jam or break. This reflection on potential pitfalls emphasizes the need for careful design consideration.

Moving jaw mechanisms have found their way into various industries, playing pivotal roles in enhancing efficiency and functionality. These systems are fundamentally based on the principle of converting linear motion into rotary motion. This conversion is essential in areas like robotics, manufacturing, and even medical equipment. For instance, in robotic arms, moving jaws help to grasp objects with precision, ensuring that tasks are performed accurately.

In the manufacturing sector, these mechanisms are used in assembly lines. They help in the automated handling of components. This reduces human error and boosts productivity. The compact design of moving jaw systems makes them ideal for tight spaces. Yet, these systems can sometimes be prone to wear and tear, requiring regular maintenance.

Tips for ensuring optimal performance include regularly checking alignment and tension to prevent jamming. Don't ignore unusual sounds, as they might signal potential failure. Also, consider the environment; high temperatures or dust might affect efficiency. Addressing these factors can prolong the lifespan of moving jaw mechanisms, ultimately saving costs in the long run.