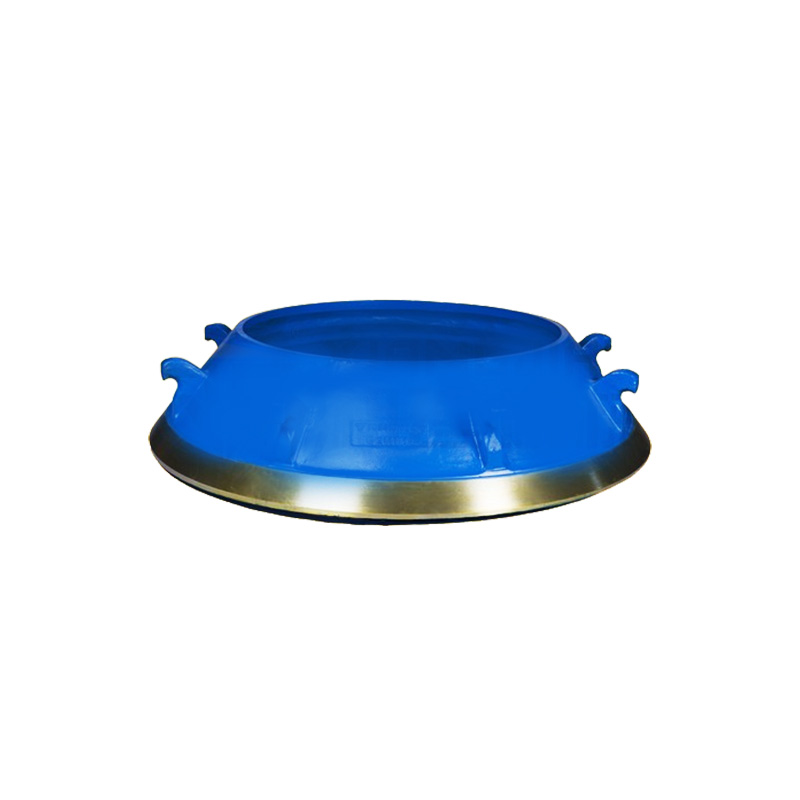

Concave & Mantle

In the quarry application o...

Cone crusher is mainly composed of moving cone and fixed cone. The motor drives the eccentric sleeve to rotate through the pulley or coupling, and then makes the moving cone do pendulum motion. When the ore enters the crushing chamber from the feed port, the distance between the moving cone and the fixed cone changes continuously. When approaching, the ore is crushed by extrusion, bending and impact; when the moving cone leaves, the crushed ore moves downward under the action of gravity and is continuously crushed until the particle size meets the requirements and is discharged from the discharge port.

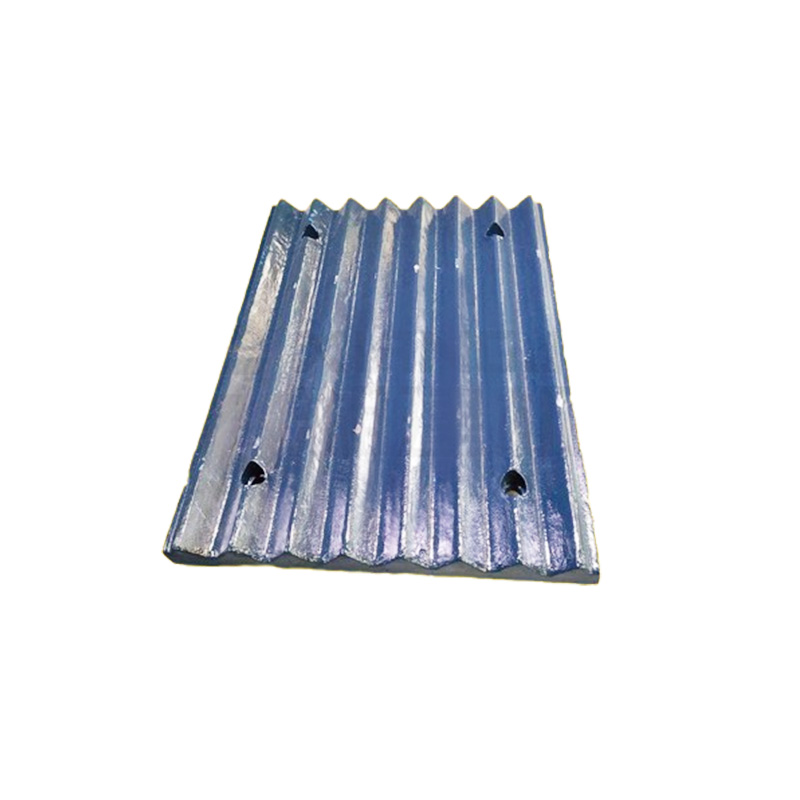

High manganese steel cone c...

High wear resistance: Under large impact or contact stress, the surface layer is rapidly hardened, and the hardening index is 5-7 times higher than other materials, which greatly improves wear resistance.

Cone crusher mantle and con...

The cone crushing wall is the key component in the cone crusher that directly contacts the material.

Bowl liner rock cone crushe...

The mantle concave is connected by casting zinc alloy. Its firmness should be checked after the cone crusher has been running for a period of time. The connection between the mortar wall and the adjustment ring is fixed by U-shaped fixing screws. Zinc alloy is cast between the mortar wall and the adjustment ring to make them tightly combined.

China Manufacturer cone cru...

Cone crusher: Cone crusher is the best choice for aggregate production and mining, featuring its unique combination of crusher speed, eccentricity and cavity type.

Cone crusher alloy manganes...

During the working process of cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric sleeve. The section where the moving cone is close to the static cone becomes the crushing chamber, and the material is crushed by multiple squeezing and impact of the moving cone and the static cone. When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone. The material to be crushed is loaded from the feed port of the cone crusher.

Cone crusher mantle and con...

When it comes to replacement cone crusher parts, Zhixin has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed and warranted replacement parts for your cone crusher, we have our unique technology, make the products service life time more durable.we are the only company have this technology in China.If not live up our promise, you can refund.

| Color | Optional |

| Material | Manganese 18/ Manganese 22 |