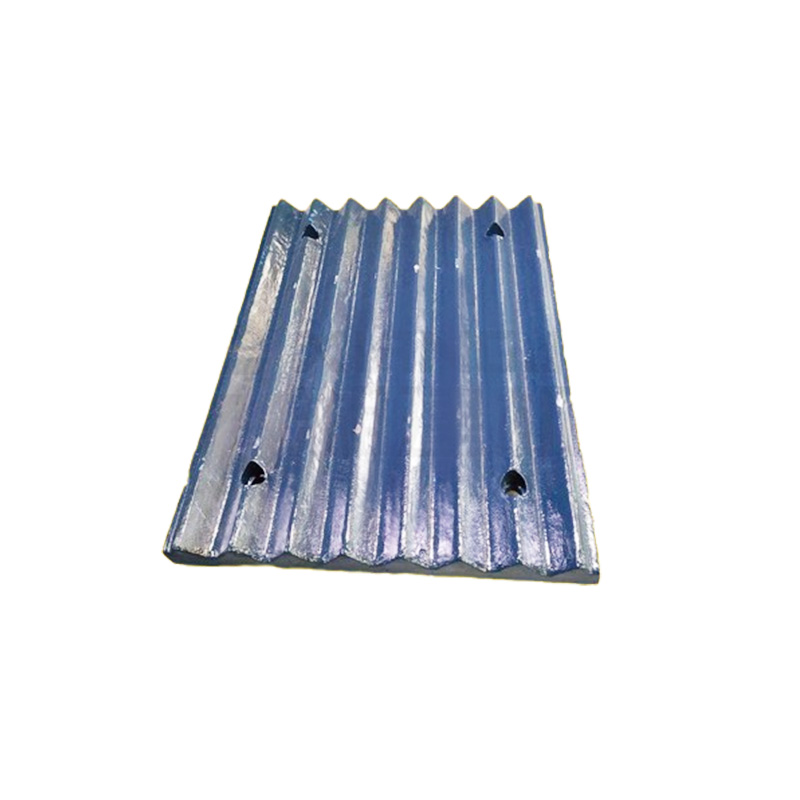

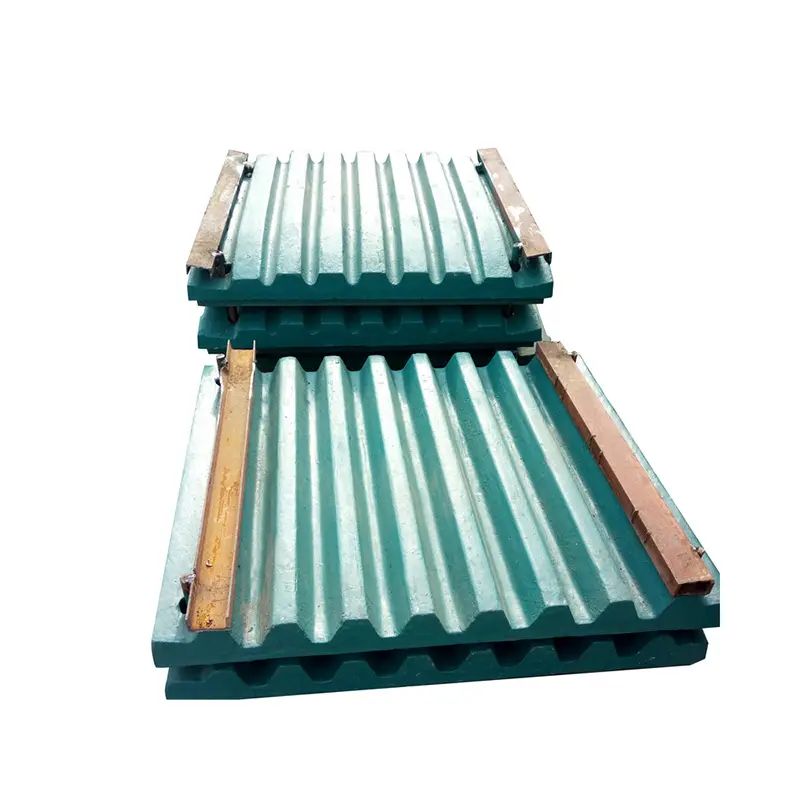

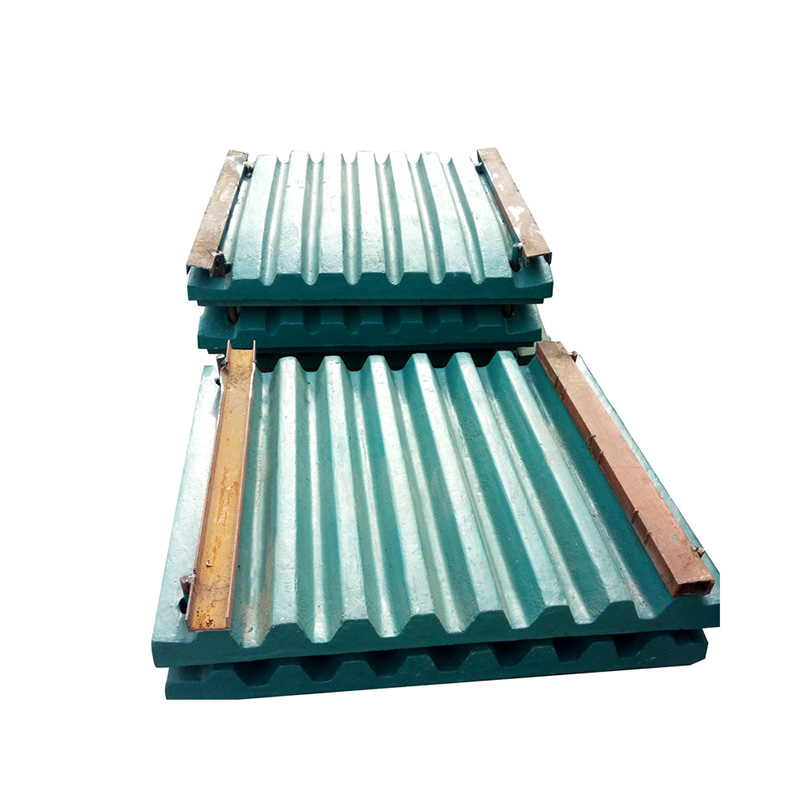

Factory Casting Ore Mining Mining Machinery Crusher Jaw Plate

Brief introduction to the jaw plates

Jaw crusher is a common coarse crushing equipment in sand and gravel production lines. It is named because it simulates the movement of the two jaws of animals to complete the material crushing operation. The output particle size is one of the important indicators of its production quality, and the size of the discharge port determines the particle size of the ore after crushing.

The jaw crusher has a history of more than 100 years since its introduction. It has the advantages of simple structure, safety and reliability, easy maintenance, and high working efficiency. It is still one of the main crushing equipment in the primary crushing of materials, but it is also recognized as one of the high-energy-consuming equipment. At present, the domestic mechanical computer-aided design and manufacturing technology has been quite popular, but compared with other similar crushing equipment, the research on the crushing mechanism and design and manufacturing of the jaw crusher is still very weak and lacking.

As the production time increases, the jaw plate will continue to wear and the discharge port will gradually become larger, which will cause certain difficulties in the next crushing operation. Therefore, in order to ensure that the production particle size meets the feeding requirements of the medium and fine crushing equipment and achieve the ideal crushing effect, it is necessary to use the adjustment device to regularly adjust the size of the discharge port. Different adjustment methods take different time, efficiency, and convenience, which will directly affect the production capacity and efficiency of the entire equipment.

Product display

Applications

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Our advantages

Chengdu Zhixin Refractory Materials is committed to the research and production of high-performance wear-resistant materials. After adding high-performance alloys, the service life of the jaw crusher jaw plate we produce is greatly increased, which can reach twice the service life of conventional jaw crusher jaw plates.

Tensile strength: more than 1500MPa.

Hardness: HRC65 to HRC68.

Impact resistance: more than 120J/cm2.

Section elongation: more than 20%.

Q & A

1. Q: What kinds of products do you offer?

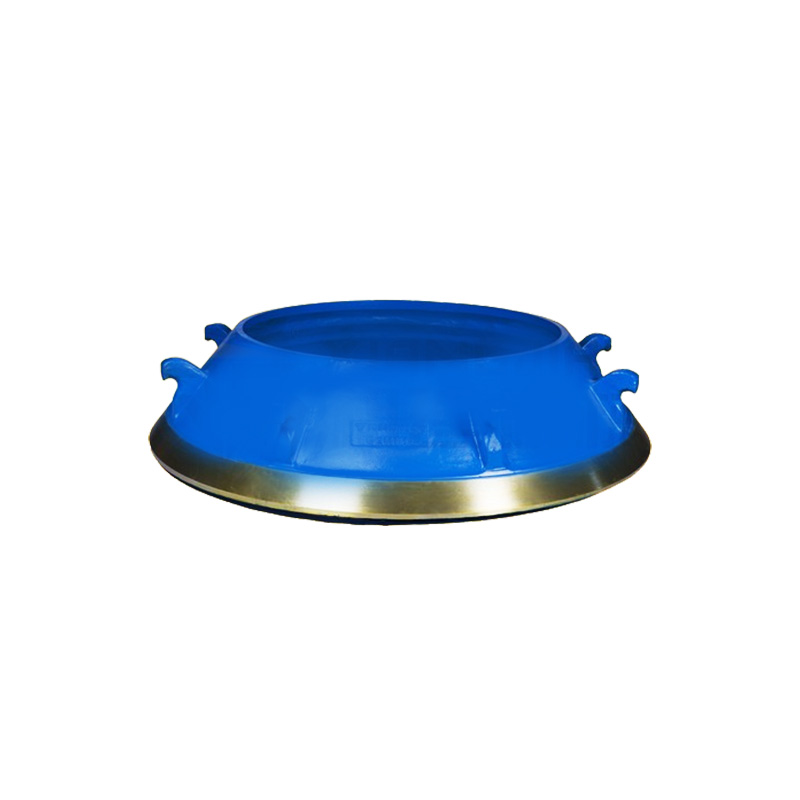

A: It ranges from ferroalloy/industrial silicon casting cooling and crushing line, the wear-resistant plates, crusher spare parts including jaw plate, cone mantle and concave, impact liner, ball mill liner etc. and excavator buckets.

2. Q: What kind of materials are you familiar with?

A: We are familiar with carbon steel, alloy steel, high manganese steel, high chrome steel, casting iron, and bronze.

3. Q: What information do we need to provide to you in order to confirm our parts order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only need to provide us with the part number, so, we may define the parts of the order.

4. Q: Would you like to accept factory inspection?

A: We are greatly welcome to our factory for your inspection.

5. Q: How do you judge sufficient components for our parts?

A: As long as the material is chosen, we shall strictly manufacture the parts according to standard.