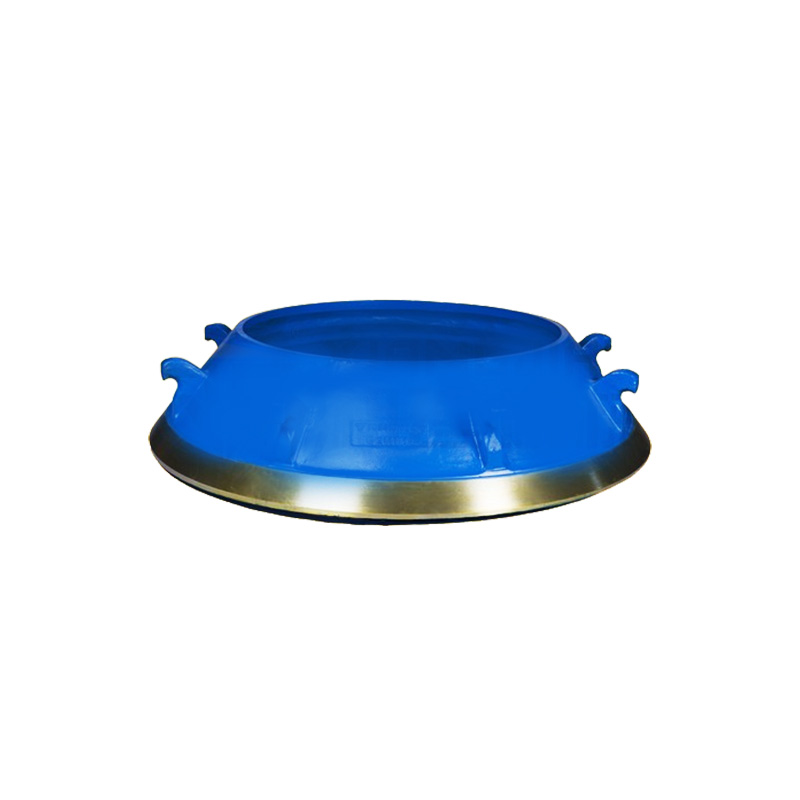

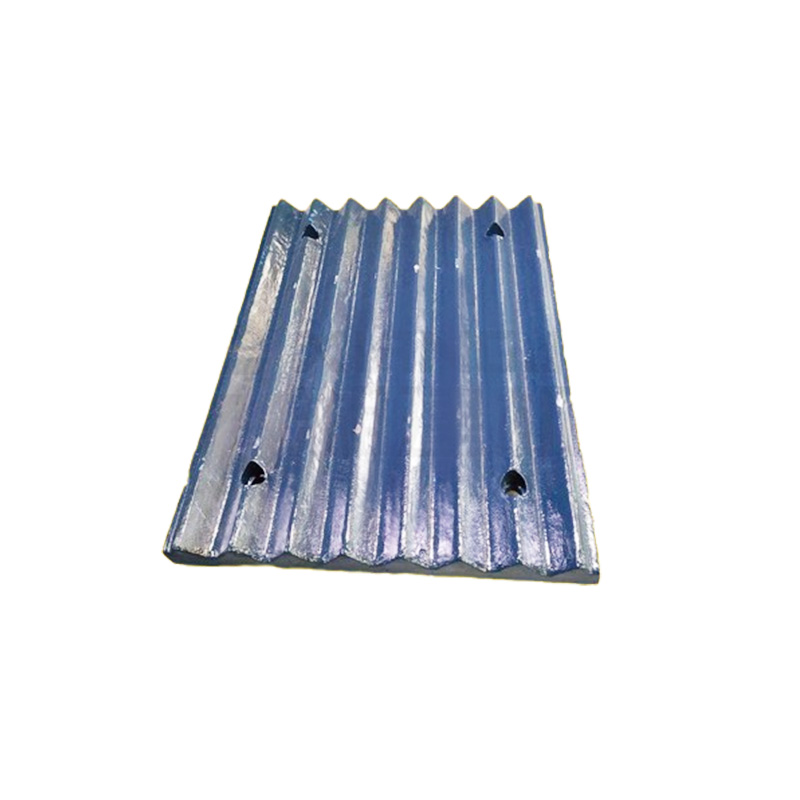

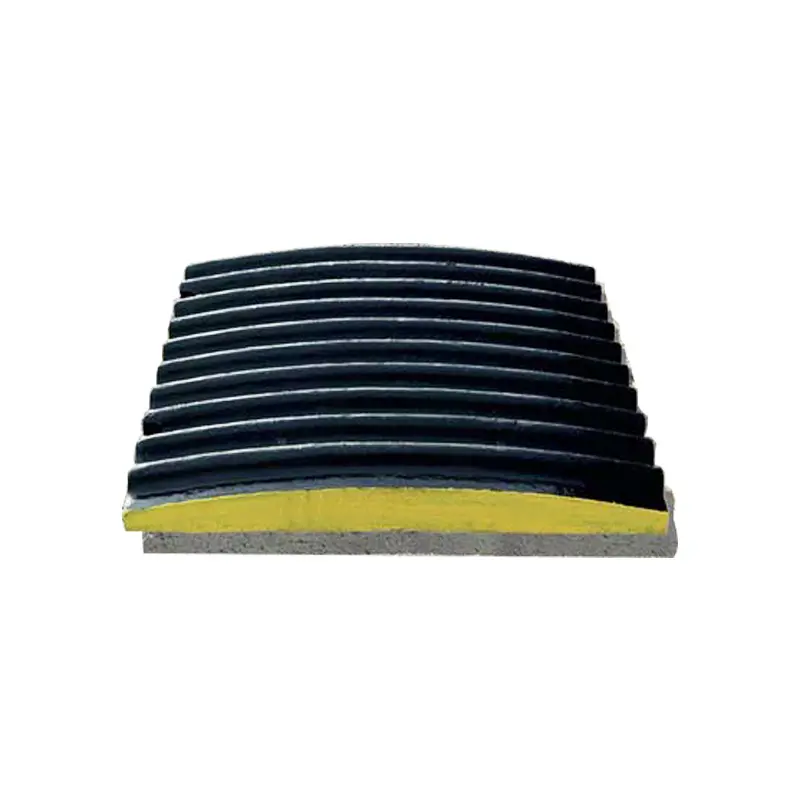

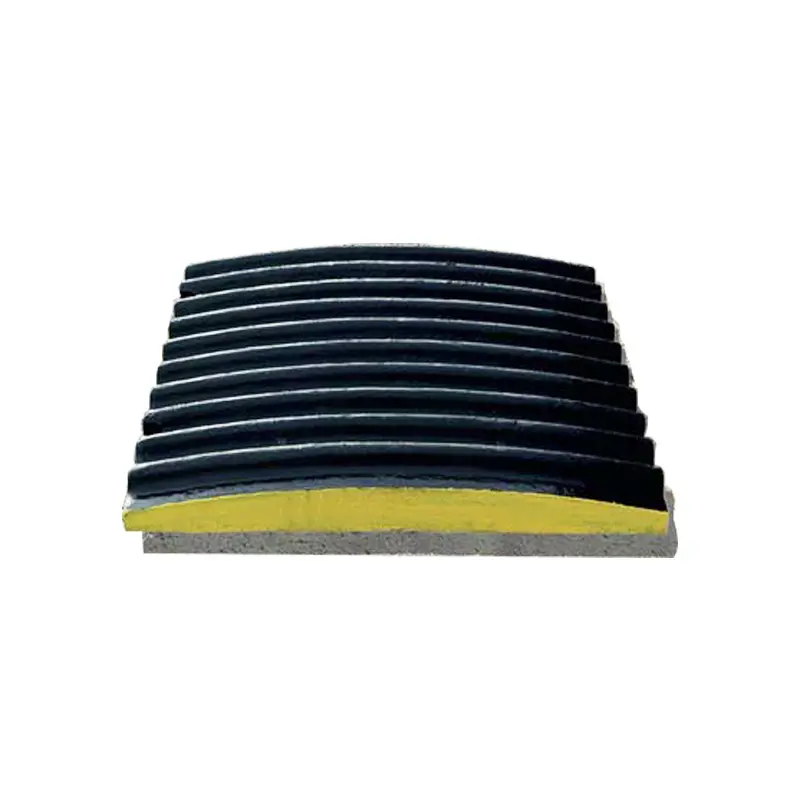

Factory Price Casting High Manganese Steel Mining Machinery Crusher Jaw Plate

Application

Suitable for mining, metallurgy, building materials, highway, railroad, water conservancy and other industries in a variety of ores and large materials in the medium size crushing.

Product display

Our services

Customized according to drawings: If you don't know the brand and model of the jaw crusher, and don't have the part number (we can't check the corresponding jaw plate drawings), you can measure the size of the jaw plate to us, our engineering design will draw a drawing for you to confirm, and finally customize the jaw plate for you according to the drawing.

Quality Assurance: All products undergo strict quality testing to ensure compliance with industry standards and customer requirements. Provide a certain period of warranty service, in the warranty period due to product quality problems caused by the failure of the product, can be repaired or replaced free of charge.

Technical support: provide comprehensive technical support services, including product selection, installation guidance, use of training, etc., to help customers better understand and improve the efficiency.

Rapid delivery: establish cooperative relationship with many logistics companies to ensure that the products can be delivered to customers in a timely and safe manner. For urgent orders, we provide expedited delivery service.

Return and exchange policy: If the product has quality problems or does not match with the customer's order, etc., we provide hassle-free return and exchange services. Customers can apply for return or exchange within the specified time after receiving the goods, and the return or exchange will be processed after confirmation.

Regular return visit: Regular return visit to customers to understand the use of products and customer satisfaction, collect customer feedback, and continuously improve the quality of products and services.

Causes of jaw plate wear:

1. The raw material enters the crushing chamber and rubs against the jaw plate. The hard raw material will be pinned to the jaw plate like a sharp blade, which will eventually cause the jaw plate to wear.

2. The raw material repeatedly rubs against the jaw plate, and cracks will form on the surface of the jaw plate. When multiple cracks are connected, the jaw plate will fall off.

3. The raw material constantly rubs against the jaw plate, and the surface material of the jaw plate will fall off and deform. The deformed part will hit the raw material again and fall off again.

Therefore, the jaw crusher jaw plate is easy to wear and needs to be replaced in a certain period of time. In order to extend its service life, its shape is generally designed to be symmetrical between the upper and lower ends, that is, it can be turned around when one end is worn. The movable jaw plate and the fixed jaw plate are the main parts used in stone crushing. The movable jaw plate is installed on the movable jaw to protect the movable jaw.