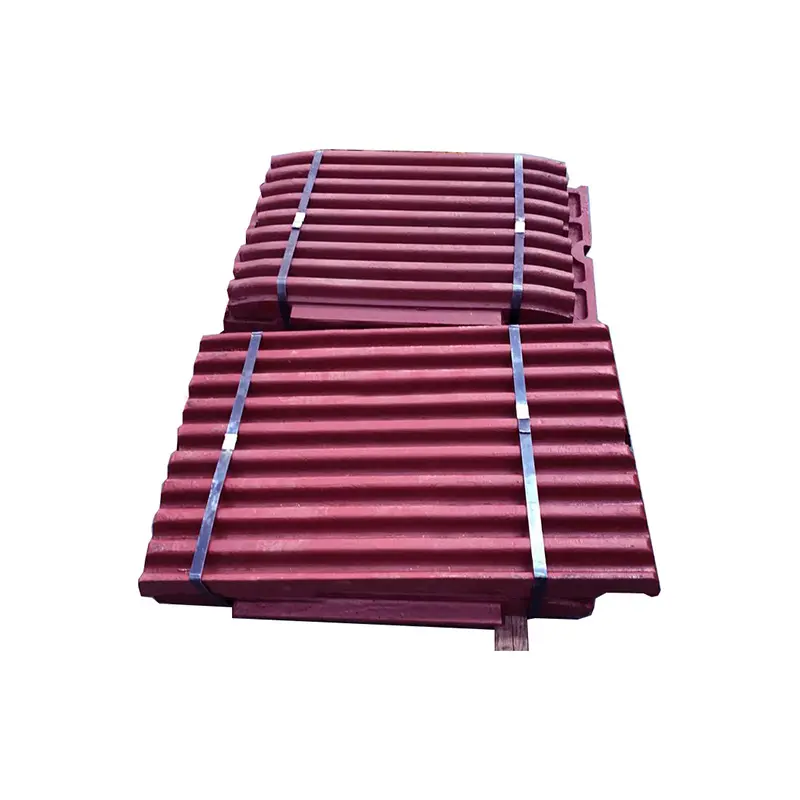

Factory Wholesale Energy & Mining New Mining Machinery Crusher Jaw Plate

Methods to extend the service life of the jaw plate

The positive suspension of the eccentric shaft device of the traditional compound swing jaw crusher is changed to negative suspension, the crusher characteristics are improved, and the jaw plate life can be extended by 50%.

The thrust plate of the traditional compound swing jaw crusher is changed to an upward inclined type, and the movable jaw jaw plate has a downward component in the direction of movement of the crushing stroke, which is conducive to crushing materials and promoting the downward movement of materials, reducing blockage. This not only improves the wear condition of the jaw plate, but also improves the processing capacity of the crusher.

Replacing the single movable jaw of the compound swing jaw crusher with a double movable jaw makes the longitudinal relative movement between the two movable jaws close to zero, eliminating the longitudinal relative movement between the jaw plates from the mechanical motion characteristics, and reducing the wear of the jaw plates.

The structural form of the movable jaw can also be changed to extend its life. Changing the flat movable jaw to a curved movable jaw can greatly reduce the excessive crushing of materials caused by poor discharge of materials at the discharge port and the resulting severe wear of the movable jaw. In order to ensure that the jaw angle is within the maximum allowable range, the ideal shape of the movable jaw jaw surface should be straight on the top and curved on the bottom.

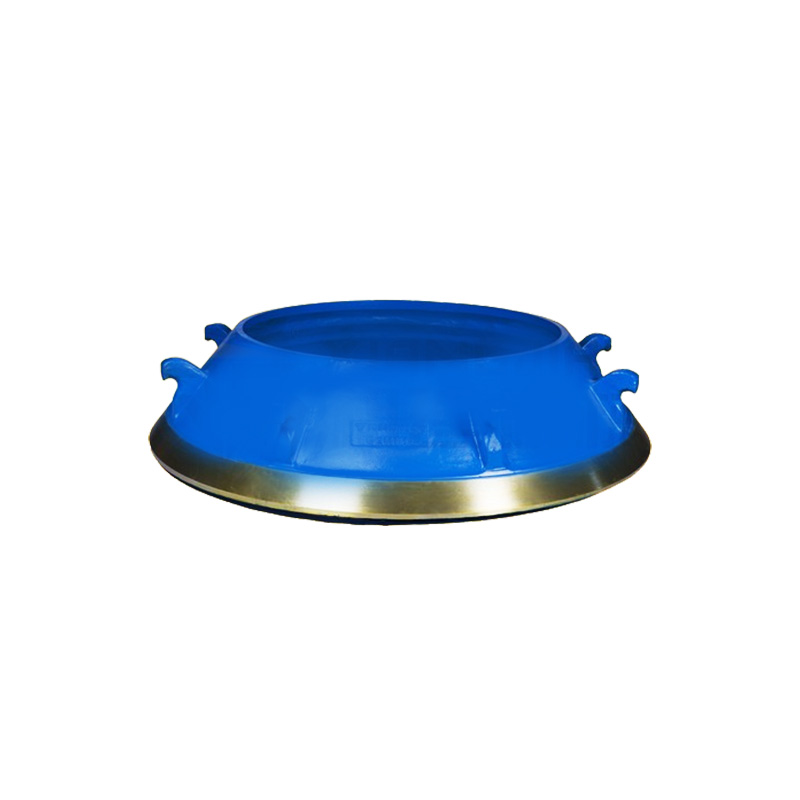

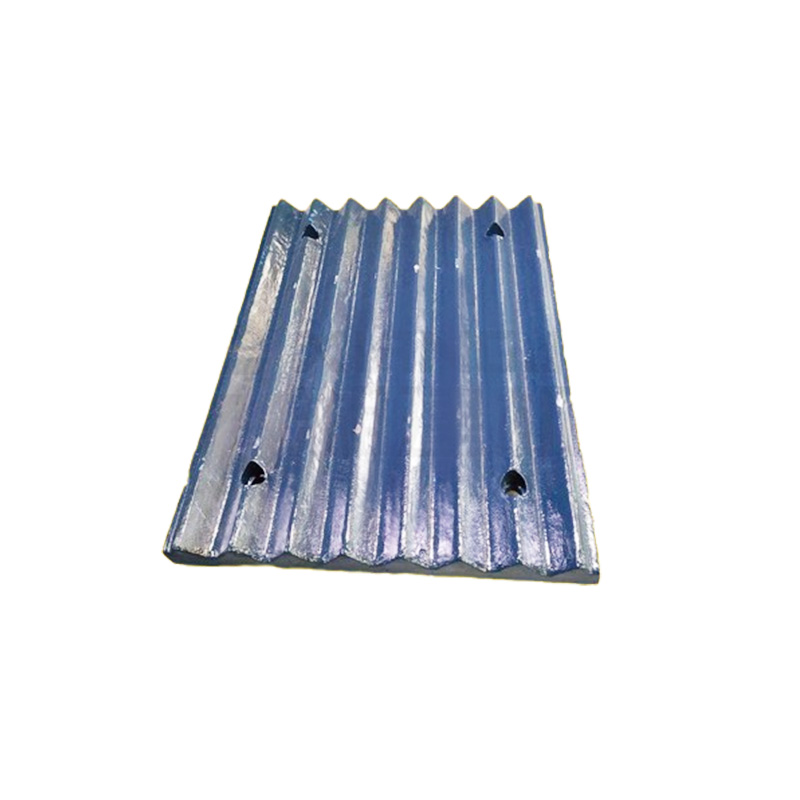

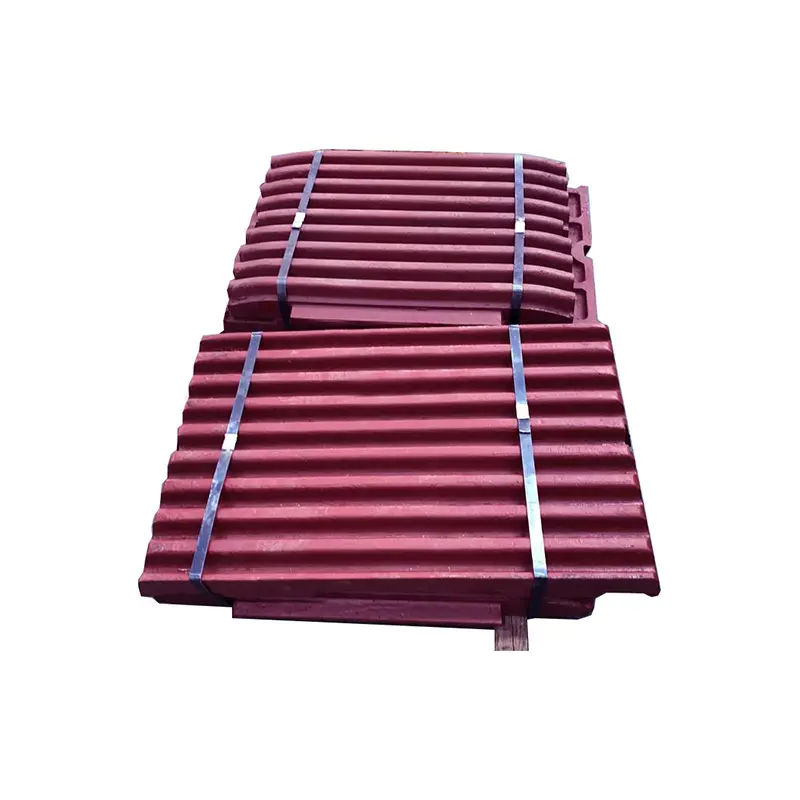

Product display

Quality Assurance

1. Purchasing with quality, control the quality activity more on supply Chain and raw material.

2. Establish the complete quality roles and responsible for every production link.

3. Conduct the total quality management.

4. Strictly carry out the quality control procedure.

5. Testing System.

Incoming raw material testing

Surface hardness testing

Core hardness testing

Chemical composition testing

Impact testing

Other testing required by customer

Our wear parts in high Mn, Cr, Mo,alloy steel of cone crusher/jaw crusher/impact crusher/hammer crusher/roller crusher .etc is with high quality and with long working life, and can be customized as customer's needs. Welcome to contact us for more details!