01020304

The leaders of Jitie Ferroalloy visited our company

2025-01-15

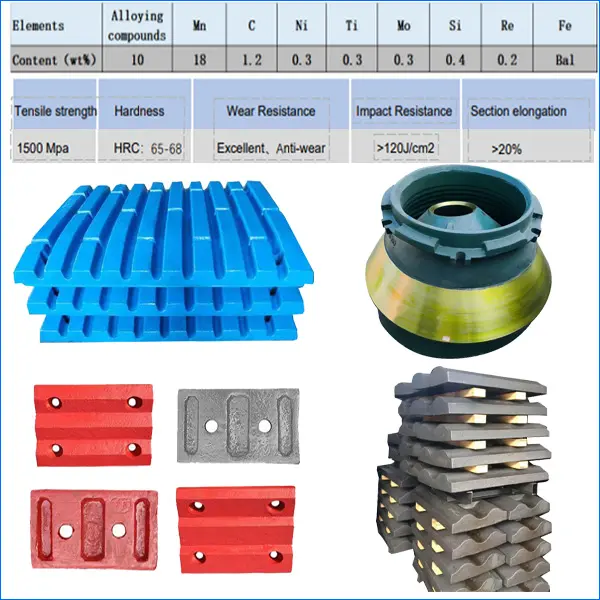

In order to solve the pain points of the industry, we have been conducting targeted research and development of high-temperature resistant materials and automated casting and crushing complete process equipment for many years. At present, the latest third-generation industrial silicon fully automatic casting, cooling and crushing system has been commercialized. All materials and processes are independently developed, which are original, scientific, advanced and practical. The whole system adopts full computer DCS touch screen automatic control. The system completely solves the automation of the series of processes of self-casting, cooling, crushing, transportation and packaging of high-temperature alloy water refined from the smelting furnace, greatly improving production efficiency and reducing quality and safety accidents. This product is especially suitable for the industrial silicon industry and has brought revolutionary progress to the industrial silicon smelting industry.

On March 13, a delegation from Jitie Ferroalloy Co., Ltd. visited our company and conducted in-depth investigation and exchanges on the crushing process and standards of the crusher. This investigation not only deepened the understanding between the two companies, but also laid a solid foundation for future cooperation between the two parties. Accompanied by the leaders and technicians of our company, the delegation first visited the production line of the crusher. The technicians gave a detailed introduction to the design concept, working principle and advantages of the crusher in practical applications. The representatives of Jitie Ferroalloy Co., Ltd. expressed great interest in the performance of the crusher and consulted in detail on the crushing standards, crushing effects and equipment operation stability.

Afterwards, the two sides had an in-depth discussion. Our company's technical team showed the representatives of Jitie Ferroalloy Co., Ltd. the crushing parameter records of the rolling mill, including crushing particle size, crushing efficiency, energy consumption and other data. Through comparative analysis and on-site demonstration, the representatives of Jitie Ferroalloy Co., Ltd. highly praised the crushing standards of our company's rolling mill, believing that its performance is stable and efficient, which meets their production needs. During the exchange, the two sides also conducted in-depth discussions on the technical innovation, market application and future development trends of the rolling mill. Our company stated that it will continue to increase investment in research and development, continuously improve the technical level and market competitiveness of the rolling mill, and provide customers with better products and services. Jitie Ferroalloy Co., Ltd. also expressed its willingness to establish a long-term cooperative relationship with our company, hoping to jointly promote the development of the rolling mill industry. This inspection activity not only demonstrated the professional strength and technical advantages of Chengdu Zhixin Refractory Technology Co., Ltd. in the field of rolling mills, but also enhanced the trust and recognition of Jitie Ferroalloy Co., Ltd. in our company. Looking into the future, Chengdu Zhixin Refractory Technology Co., Ltd. will continue to uphold the concept of "customer first, quality first", continuously improve product quality and service level, and work hand in hand with partners such as Jitie Ferroalloy Co., Ltd. to create a better future.